How Pulleys make your industrial work easier?

In modern industries, efficiency, safety, and reliability are essential for staying competitive. One of the simplest yet most effective tools that help achieve these goals is the pulley.

Whether it’s lifting heavy loads, running conveyor systems, or improving power transmission, pulleys play a crucial role in reducing manual effort and maximizing productivity.

A pulley works on the basic principle of changing the direction of force, but its industrial applications go far beyond that. Today, manufacturers use different pulley types such as V-belt pulleys, flat belt pulleys, taper lock pulleys, and timing pulleys to meet specific operational needs.

These components are widely used in sectors like manufacturing, mining, construction, and material handling to move goods and machinery with precision.

By reducing strain on workers and machinery, pulleys not only make operations faster but also extend equipment life and ensure workplace safety. For industries looking to improve workflow and minimize downtime, choosing the right pulley system is a smart investment.

In this blog, we’ll explore how pulleys work, the types available, their benefits, and why partnering with a trusted V-belt pulley manufacturer like Nisuka Industries can help you achieve better results.

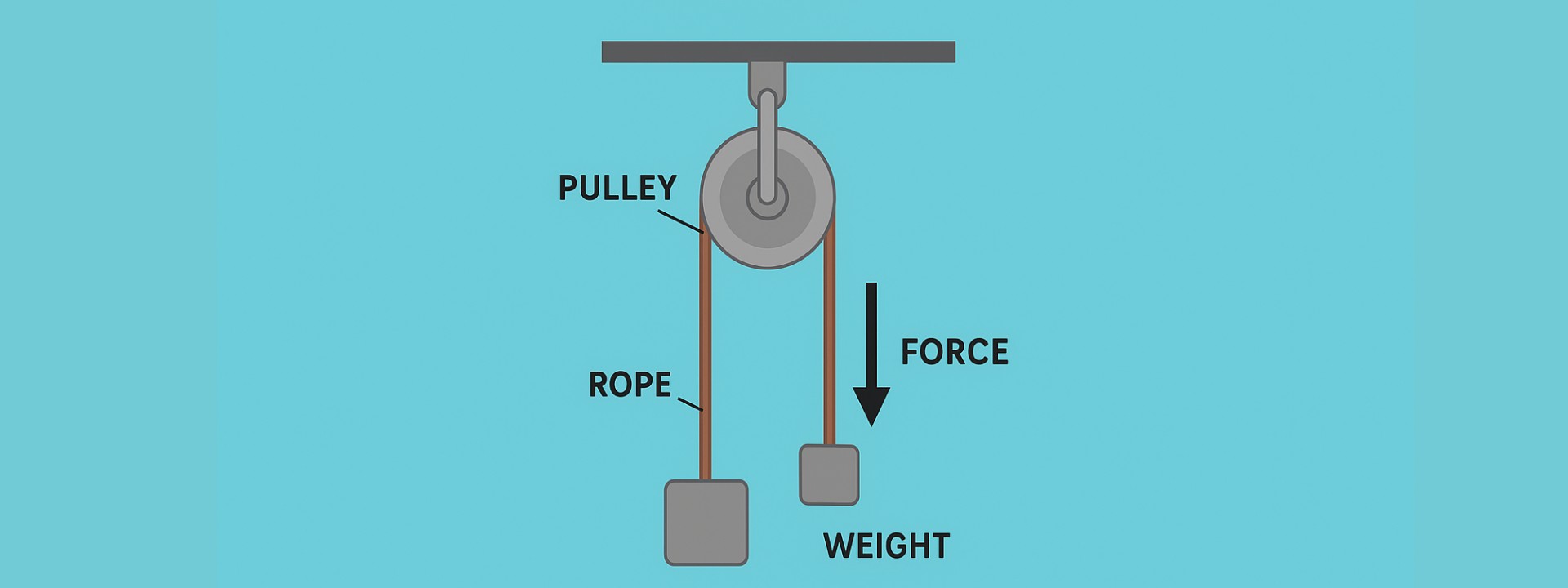

What Is a Pulley?

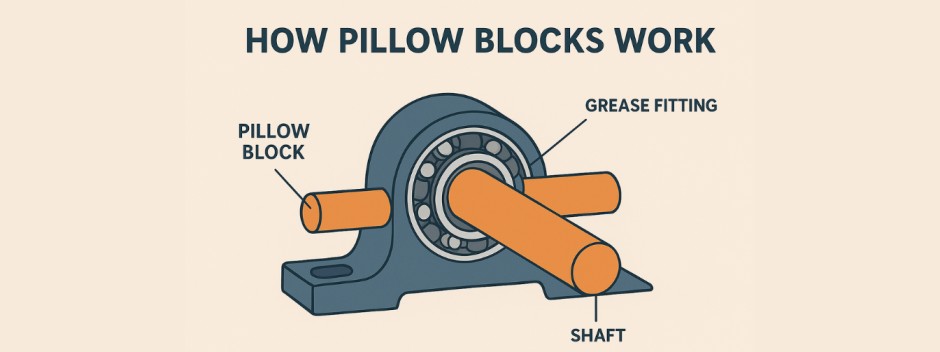

A pulley is a wheel with a groove along its circumference, designed to hold and guide a rope, belt, or chain. This simple yet powerful device transforms the direction and magnitude of force applied, allowing operators to lift or move heavy loads with less effort.

In industries, pulleys are often mounted on machines, shafts, or structural frames, forming the backbone of equipment such as conveyors, cranes, and elevators.

Despite their simplicity, pulleys can handle large loads and operate continuously in demanding industrial environments, proving their reliability and efficiency.

How Does a Pulley Work?

Pulleys work by redirecting force and distributing weight evenly. When a rope or belt runs over the pulley wheel, applying force at one end moves the load at the other end with reduced effort. The mechanical advantage depends on the pulley system: single pulleys change the direction of force, while multiple or compound pulleys reduce the effort required to lift heavy weights.

In industrial setups, pulleys are often connected to motors or gearboxes, converting rotational motion into linear motion or driving conveyor belts. This enables smooth, continuous operations, minimizes manual labor, and enhances both safety and productivity.

Types of Pulley Used in Industries

Industrial applications use a variety of pulleys based on operational needs. Fixed pulleys are stationary and mainly change force direction, while movable pulleys reduce the lifting effort. Compound pulleys combine fixed and movable systems for greater mechanical advantage.

Specialized pulleys like V-belt pulleys, timing pulleys, drum pulleys, and magnetic pulleys are essential in conveyors, manufacturing equipment, and material-handling systems. Selecting the right pulley type depends on load, speed, and durability requirements, ensuring efficient and safe industrial operations.

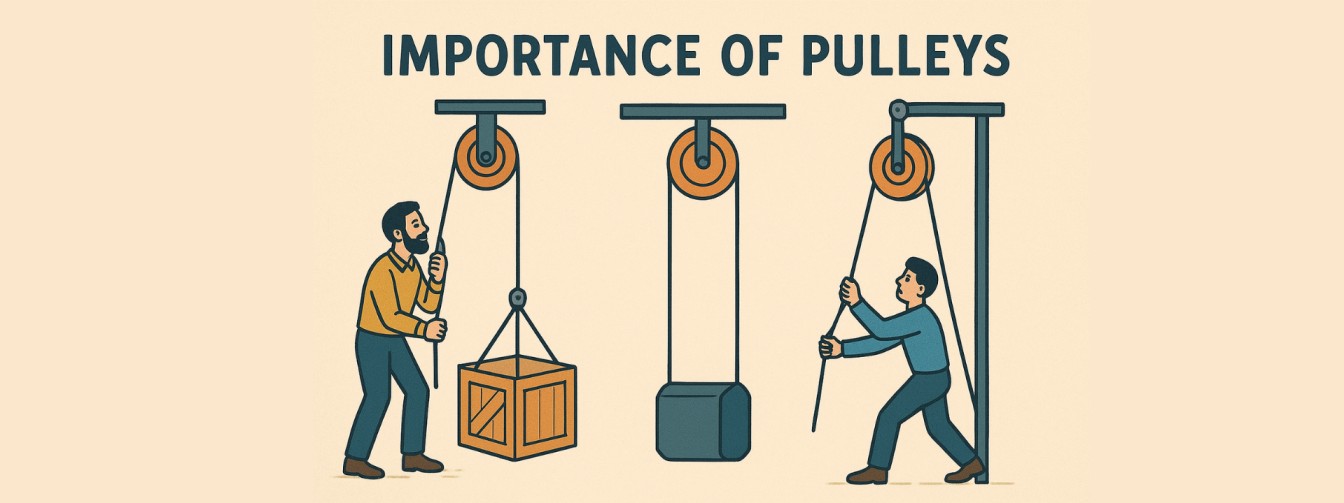

Importance of Pulley

Pulleys are indispensable in industrial operations, offering a simple yet highly effective solution for handling heavy loads and improving workflow efficiency.

In industries ranging from manufacturing and mining to construction and material handling, pulleys are crucial for lifting, moving, and controlling heavy objects with minimal effort.

Their primary advantage lies in reducing manual labor while ensuring precision and safety during operations. By distributing weight evenly and redirecting force, pulleys enable operators to move materials efficiently, even in challenging environments.

Beyond lifting, pulleys play a pivotal role in mechanical systems such as conveyor belts, hoists, cranes, and automated machinery. They facilitate smooth motion, reduce wear on equipment, and optimize energy usage. This not only increases productivity but also prolongs the lifespan of machinery, which is vital for cost-effective industrial operations.

Furthermore, pulleys provide flexibility in system design, allowing engineers to adapt machines to specific operational requirements.

Industries that rely on repetitive lifting or continuous motion, such as assembly lines or bulk material handling, benefit greatly from pulleys. Their reliability, low maintenance, and versatility make them a preferred choice for industrial engineers and facility managers.

By integrating pulley systems, industries can enhance efficiency, safety, and overall operational performance, making pulleys a cornerstone of modern industrial applications.

Why Pulley Are Essential for Heavy Machinery

Heavy machinery often involves lifting or moving massive loads that would be impossible with human strength alone. Pulleys are essential in such scenarios because they reduce the effort required to operate these machines.

By changing the direction of applied force and distributing weight effectively, pulleys allow operators to lift and maneuver heavy equipment safely.

In industrial environments, pulleys are often integrated into cranes, hoists, and winches. They enable the smooth transfer of loads while minimizing strain on both machinery and operators. This is especially critical in construction, manufacturing, and mining, where even minor inefficiencies can lead to operational delays or safety hazards.

Pulleys also enhance precision in load handling, ensuring that heavy materials can be positioned accurately without risk of damage.

Moreover, pulley systems reduce wear and tear on mechanical components. By efficiently transmitting force, they prevent undue stress on shafts, belts, and motors, extending the life of machinery and lowering maintenance costs.

Their role in safety, efficiency, and durability makes pulleys indispensable in any operation involving heavy industrial equipment.

Pulley Systems and Load Handling Efficiency

Pulley systems significantly enhance load-handling efficiency by providing mechanical advantage, allowing workers to move heavier loads with less effort.

A simple pulley changes the direction of force, while compound or block-and-tackle systems multiply mechanical advantage, reducing the energy required to lift or transport objects.

In industrial settings, efficient load handling is critical for productivity. Conveyor systems, cranes, and automated assembly lines often rely on pulleys to move materials continuously and reliably. Pulleys reduce friction and wear on moving parts, ensuring smoother operations and preventing downtime caused by equipment failure.

Additionally, pulley systems contribute to workplace safety. By reducing the manual effort needed to lift heavy loads, they lower the risk of injuries and accidents. This efficiency not only saves time but also allows businesses to handle larger volumes of materials, improving throughput and operational performance.

Selecting the right pulley type and configuration is essential to maximize efficiency, making pulleys a strategic investment in any industrial workflow.

How Pulley Simplify Industrial Operations?

Pulleys play a crucial role in modern industrial operations by transforming complex, labor-intensive tasks into manageable, efficient processes. Their primary function is to reduce the effort required to lift, move, or transfer heavy materials, which directly impacts productivity and operational efficiency.

In factories, warehouses, construction sites, and mining facilities, pulley systems are integrated into conveyors, hoists, cranes, and other machinery, enabling smooth and continuous material movement.

The simplicity of pulleys allows for quick installation and minimal training for operators, making them accessible and practical for diverse industrial environments. Their mechanical advantage ensures that even large or awkwardly shaped loads can be handled with precision, reducing the time and effort required for manual handling.

Additionally, pulleys allow for more flexible equipment layouts, as belts, ropes, or chains can redirect force in multiple directions, optimizing space and workflow.

By incorporating pulley systems, industries can streamline operations, reduce worker fatigue, and improve overall productivity. The combination of mechanical efficiency, reliability, and ease of use makes pulleys a cornerstone of industrial operations, and working with a trusted Plummer Block manufacturer ensures high-quality components that have a profound impact on complex industrial workflows.

1.Reducing Manual Effort and Increasing Productivity

One of the most significant advantages of pulleys in industrial settings is their ability to reduce manual effort. By redirecting force and providing mechanical advantage, pulleys allow workers to lift and transport heavy materials with far less exertion.

In manufacturing and material-handling facilities, this translates to faster operations and higher throughput.

For example, in conveyor systems, pulleys drive belts that move raw materials, finished goods, or machinery components seamlessly across production lines.

This automation reduces the reliance on manual labor while increasing precision and consistency in operations. Additionally, with reduced physical strain, workers can focus on skilled tasks rather than energy-intensive lifting, enhancing productivity and operational efficiency.

2.Ensuring Safety and Smooth Operation

Pulleys improve workplace safety by minimizing the physical strain on employees and reducing the risk of accidents during material handling. Heavy loads can be moved smoothly without sudden jerks or uneven motion, preventing damage to goods and equipment.

Properly designed pulley systems also reduce wear on machinery components, ensuring long-lasting and reliable operation in demanding industrial environments.

3.Cost-Effectiveness and Maintenance Benefits

Pulleys are highly cost-effective due to their simple design and durability. They require minimal maintenance compared to more complex machinery, which reduces downtime and lowers operational costs.

Industrial pulleys can operate continuously in harsh conditions, with replacement or servicing of components like belts or bearings being quick and inexpensive.

By combining low maintenance, operational reliability, and high efficiency, pulley systems deliver long-term value to industrial businesses, making them a smart investment for companies looking to improve workflow efficiency without escalating costs.

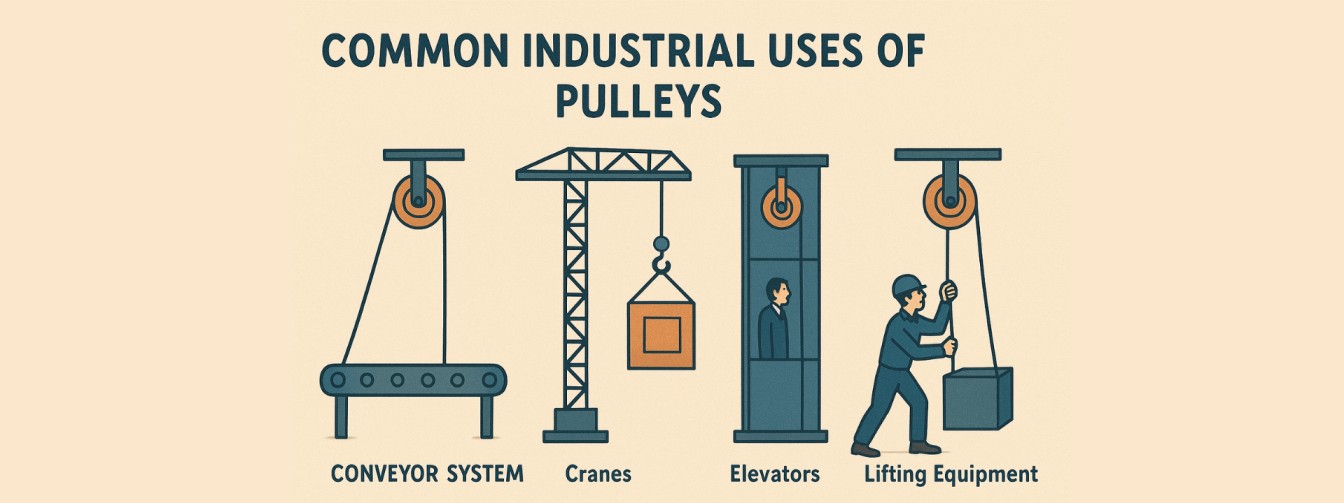

Industrial Uses of Pulley

Pulleys are versatile components used extensively across various industrial sectors to facilitate motion, lifting, and power transmission.

Their adaptability allows them to meet the unique needs of industries ranging from manufacturing and automotive to construction and material handling. By providing mechanical advantage, pulleys reduce manual effort, improve workflow efficiency, and ensure safety during operations.

In industrial setups, pulleys are often integrated into complex machinery and systems, including conveyor belts, hoists, cranes, and automated assembly lines. They enable smooth transfer of materials, precise control over heavy loads, and efficient operation of mechanical equipment.

Their reliability, low maintenance, and cost-effectiveness make pulleys a fundamental tool in modern industries. Selecting the right type of pulley—fixed, movable, or compound—is essential to maximize efficiency and meet operational requirements.

Pulley in Conveyor Systems

Conveyor systems are among the most common industrial applications of pulleys. Pulleys drive conveyor belts that transport raw materials, components, or finished products efficiently across manufacturing floors, warehouses, and distribution centers.

By redirecting force and maintaining tension, pulleys ensure smooth belt movement, reduce energy consumption, and prevent operational delays caused by slippage or uneven motion.

In addition to driving belts, specialized pulleys such as drum pulleys, V-belt pulleys, and timing pulleys are used to regulate speed, direction, and load distribution. These pulleys contribute to the continuous and reliable operation of conveyor systems, improving productivity and reducing labor costs.

In industries like mining or recycling, magnetic pulleys help separate ferrous materials, further enhancing operational efficiency.

Role of Pulley in Lifting and Hoisting Applications

Pulleys are critical for lifting and hoisting applications, allowing workers to raise heavy loads with minimal effort. Fixed pulleys change the direction of force, movable pulleys reduce the effort needed, and compound pulley systems combine both advantages to maximize mechanical efficiency.

In construction, warehouses, and shipyards, pulleys are used in cranes, winches, and hoists to lift heavy equipment, machinery, and materials safely. By distributing weight evenly and reducing manual effort, pulleys help prevent workplace injuries and ensure precise load positioning. They also minimize wear on lifting equipment, extending operational life and lowering maintenance costs.

Automotive and Manufacturing Industries

In automotive and manufacturing industries, pulleys are essential for transmitting rotational motion between shafts, driving machinery, and ensuring synchronized operations. V-belt and timing pulleys are commonly used in engines, assembly lines, and CNC machines to maintain precise speed and alignment.

Pulleys in these sectors increase efficiency, reduce downtime, and allow smooth coordination between different mechanical components. From powering conveyor belts to controlling robotic arms, pulleys enhance operational accuracy, productivity, and overall reliability. Collaborating with a trusted SMSR Gearbox manufacturer ensures that pulley-driven systems and gearboxes work seamlessly together, proving that even simple mechanical components can deliver a significant impact on modern industrial efficiency.

Choosing the Right Pulley for Your Business

Selecting the right pulley is critical for ensuring efficiency, safety, and durability in industrial operations. A poorly chosen pulley can lead to equipment failure, increased maintenance costs, and reduced productivity.

Businesses need to carefully evaluate operational requirements, load capacities, speed, and environmental conditions before making a decision.

The choice of a pulley depends on its intended application—whether it’s for lifting heavy materials, driving conveyor belts, or transmitting rotational motion between shafts. Different types of pulleys, such as fixed, movable, V-belt, timing, drum, or magnetic pulleys, are designed to handle specific tasks. Using the correct pulley type ensures optimal mechanical advantage, smooth operation, and energy efficiency.

In addition to functionality, compatibility with existing machinery is crucial. Pulleys must align with shaft sizes, belt types, and operational speeds to prevent wear, reduce downtime, and maintain productivity.

By carefully selecting pulleys based on their operational, mechanical, and environmental requirements, businesses can maximize efficiency while minimizing costs and safety risks.

1.Factors to Consider When Selecting a Pulley

When choosing a pulley, several key factors must be considered. First is load capacity—the pulley must support the weight of the material or equipment without compromising safety. Second is speed and rotational efficiency, which ensures that the pulley can handle operational speeds without slipping or overheating.

Environmental conditions are also important. Pulleys used in outdoor or harsh industrial environments should resist corrosion, extreme temperatures, and dust. The mechanical compatibility with belts, chains, or shafts is another factor, as mismatched components can cause premature wear or equipment failure. Maintenance requirements, durability, and long-term operational costs should also influence the selection process.

By evaluating these factors, businesses can choose pulleys that improve performance, safety, and reliability.

2.Material and Design Options

Pulleys are available in a variety of materials and designs to suit different industrial needs. Steel and cast iron pulleys offer high strength and durability for heavy-duty applications, while aluminum pulleys are lightweight and ideal for moderate loads. Plastic or composite pulleys are used in environments where corrosion resistance and quiet operation are critical.

Design options also vary based on application. V-belt pulleys provide efficient power transmission and reduce slippage, whereas timing pulleys ensure synchronized motion between shafts. Drum pulleys and magnetic pulleys are common in conveyor systems for bulk material handling. Selecting the right combination of material and design ensures longevity, operational efficiency, and cost-effectiveness, helping businesses achieve smooth and reliable industrial operations.

Conclusion

Pulleys may seem like simple mechanical devices, but their impact on industrial operations is immense. By reducing manual effort, improving efficiency, and ensuring safety, pulleys have become indispensable in industries such as manufacturing, construction, automotive, and material handling. Whether integrated into conveyor systems, hoists, cranes, or automated machinery, pulleys streamline workflows, save energy, and allow heavy loads to be moved with precision.

The versatility of pulleys—from fixed and movable to compound, V-belt, timing, drum, and magnetic types—means businesses can select systems tailored to their operational requirements. Understanding what is Taper Lock Pulley and its advantages is essential when choosing the right pulley for heavy-duty applications. Factors such as load capacity, speed, material, and environmental conditions play a crucial role in maximizing performance and durability. Properly selected pulleys not only enhance productivity but also reduce maintenance costs, extend equipment lifespan, and ensure worker safety.

In today’s fast-paced industrial world, efficiency, reliability, and safety are paramount. Pulleys, though simple in design, deliver on all these fronts, proving that the right mechanical solution can significantly elevate industrial performance. By understanding their types, applications, and advantages, businesses can harness the full potential of pulleys, making them a true game-changer for modern industrial operations.

FAQS

How does a pulley make our work easier?

A pulley is a simple mechanical device that changes the direction of force, allowing us to lift or move heavy objects with ease. What Is a Pulley explains that it reduces manual effort, making tasks faster and safer. How Does Pulley Work in industrial settings by distributing weight and providing mechanical advantage. The Importance of Pulleys lies in improving efficiency and reducing strain, while Industrial Uses of Pulleys include conveyors, cranes, and material handling. Nisuka Industries offers high-quality pulley solutions for various industrial applications, ensuring reliability and performance.

What are the benefits of using a pulley?

Using a pulley offers multiple advantages, including reducing manual labor, increasing efficiency, and ensuring smooth operations. What Is a Pulley highlights its simplicity and reliability. How Does Pulley Work shows it multiplies force and changes direction for easier lifting. The Importance of Pulleys is evident in both safety and productivity. In Industrial Uses of Pulleys, benefits include power transmission, load handling, and minimizing wear on machinery.

How are pulleys important to engineering?

The Importance of Pulleys in engineering cannot be overstated—they allow efficient power transmission and precise load control. Understanding What Is a Pulley helps engineers design systems that maximize mechanical advantage. How Does Pulley Work enables effective integration into machines and conveyor systems. Industrial Uses of Pulleys demonstrate their versatility in construction, manufacturing, and automotive engineering, making them essential components for safe, efficient, and cost-effective operations.

Can pulleys reduce energy consumption?

Yes, pulleys optimize mechanical efficiency. Knowing What Is a Pulley helps in designing systems that save energy. How Does Pulley Work by providing mechanical advantage, requiring less force to move loads. The Importance of Pulleys extends to energy savings and operational cost reduction. In various Industrial Uses of Pulleys, this efficiency allows machinery to run longer with minimal power, improving overall productivity.

How do pulleys improve workplace safety?

The Importance of Pulleys in safety is significant—they reduce manual lifting and prevent strain injuries. Understanding What Is a Pulley ensures proper implementation in machinery. How Does Pulley Work to control load movement smoothly, while Industrial Uses of Pulleys like cranes and hoists minimize accidents and material damage. Pulleys make operations safer, efficient, and reliable.

Why are pulleys considered essential in modern engineering?

What Is a Pulley explains its role as a fundamental mechanical tool. How Does Pulley Work shows it reduces effort and improves precision. The Importance of Pulleys is evident in productivity, safety, and energy efficiency. Industrial Uses of Pulleys span manufacturing, automotive, and construction industries, proving pulleys are essential for efficient, cost-effective, and reliable operations.