Top 10 Industrial Gearbox Maintenance Tips to Improve Efficiency and Lifespan

In every modern manufacturing setup, the gearbox plays a vital role in keeping operations smooth and efficient. Whether it’s a SMSR Gearbox, helical, or worm gearbox, its performance directly affects the productivity and reliability of the entire system. Over time, continuous load, heat, and vibration can lead to wear and tear — making industrial gearbox maintenance an essential practice for every plant manager and engineer.

A proper gearbox maintenance checklist not only prevents unexpected breakdowns but also helps improve energy efficiency, reduce noise, and extend the overall lifespan of the machinery. By following proven gearbox preventive maintenance steps — such as regular lubrication, alignment checks, and vibration monitoring — industries can ensure consistent performance under heavy operating conditions.

This blog highlights the top 10 industrial gearbox maintenance tips that can significantly enhance machine reliability and minimize downtime. Whether you handle daily inspections or schedule professional industrial gearbox service and repair, these actionable insights will help you maintain long-term efficiency and safety. Leading industries and SMSR gearbox manufacturer like Nisuka Industries emphasize the importance of routine care, proper lubrication, and preventive servicing to ensure consistent performance. Let’s explore how small preventive steps can create a big impact on your gearbox’s efficiency, durability, and overall industrial output.

1.Schedule Routine Gearbox Inspections

Routine inspections are the foundation of a reliable gearbox maintenance checklist. They help detect early warning signs like oil leaks, vibration, or abnormal noise before they turn into serious damage. Regular inspection also ensures that gears, bearings, and seals are working smoothly. A visual inspection every week and a full inspection every month can prevent downtime and save repair costs.

In industrial gearbox maintenance, inspections should include checking oil levels, motor alignment, and temperature readings. Using vibration sensors and infrared thermometers helps identify problems early. A technician should record each observation for future reference.

Following this routine is part of smart gearbox preventive maintenance, as it gives you time to plan repairs rather than react to breakdowns. It also reduces the frequency of unexpected industrial gearbox service and repair. In short, routine inspections keep operations running smoothly, increase gearbox efficiency, and extend the lifespan of your machinery. For anyone managing heavy-duty equipment, this simple practice serves as a complete guide of gearbox maintenance—helping you maintain reliability, safety, and long-term performance.

2.Maintain Proper Lubrication Levels

Lubrication is the lifeline of any gearbox. It minimizes friction, controls heat, and reduces wear between gears. In your gearbox maintenance checklist, checking and maintaining proper lubrication levels should be a top priority. Insufficient or contaminated oil can lead to overheating, misalignment, and gear tooth damage.

During industrial gearbox maintenance, always inspect oil levels, clarity, and viscosity. If you notice sludge, foam, or metallic particles, it’s time to replace the oil. Always use clean tools when refilling to avoid contamination. Proper lubrication also improves energy efficiency and prevents mechanical losses.

A strong gearbox preventive maintenance plan includes scheduled oil analysis to track contamination levels. It’s a simple step that prevents thousands in repair costs. When lubrication is well-managed, the need for industrial gearbox service and repair becomes rare. Keeping your gearbox properly oiled guarantees smooth performance and a longer operating life for heavy-duty equipment.

3.Use Only Manufacturer-Recommended Lubricants

Every gearbox model is designed to perform best with a specific type of oil. Using the wrong lubricant can cause serious problems like overheating, corrosion, or premature gear wear. That’s why your gearbox maintenance checklist must include using only manufacturer-approved lubricants.

Proper oil selection is a crucial part of industrial gearbox maintenance. Manufacturers test and recommend lubricants that match their gear materials, speeds, and load conditions. Using substitutes can reduce oil life and damage critical parts. Always check the manual before changing the oil type or brand.

In gearbox preventive maintenance, the right oil prevents metal-to-metal contact and forms a protective layer that minimizes wear. Always store lubricants in sealed containers to prevent contamination. This simple discipline saves a significant amount on industrial gearbox service and repair costs. Following manufacturer guidelines ensures consistent performance, longer gear life, and greater operational safety across all applications.

4.Monitor Temperature and Vibration Regularly

Monitoring temperature and vibration levels gives you valuable insight into gearbox health. These are the most common indicators of internal problems such as imbalance, bearing failure, or misalignment. Including this step in your gearbox maintenance checklist helps detect problems early and prevents severe damage.

In industrial gearbox maintenance, use sensors or handheld devices to track vibration trends and temperature variations. A sudden rise in either means something is wrong — possibly a lubrication issue or gear misalignment. Addressing these signals early reduces downtime and prevents costly damage. Understanding these warning signs also connects closely to the factors to choosing the right conveyor gearbox, since selecting a gearbox with the correct load capacity, speed ratio, and material quality plays a crucial role in long-term performance and reliability.

Smart factories now use IoT-based gearbox preventive maintenance systems that alert technicians automatically when readings exceed safe limits. This predictive approach ensures continuous monitoring without human error.

By observing these parameters closely, you can prevent overheating, reduce noise, and avoid emergency industrial gearbox service and repair. Consistent tracking also improves gearbox efficiency, extends service life, and keeps operations safe under high-load conditions.

5.Keep Seals and Bearings Clean and Tight

Seals and bearings are critical components that ensure smooth power transmission inside the gearbox. They prevent contamination and maintain lubrication levels. Keeping them clean and tight is an essential step in every gearbox maintenance checklist.

During industrial gearbox maintenance, inspect seals for cracks or leaks. Even a small oil leak can lead to lubrication loss and increased friction. Bearings should rotate freely without any vibration or noise. Clean these parts using lint-free cloths and approved cleaning agents to remove dust or grease buildup.

In gearbox preventive maintenance, timely replacement of worn-out seals or bearings prevents oil contamination and overheating. When these components are well-maintained, the gearbox runs quietly and efficiently.

Neglecting this step often leads to costly industrial gearbox service and repair. Clean and tight seals maintain internal pressure and protect against dust and moisture — ensuring your gearbox performs reliably for years under heavy-duty conditions.

6.Check for Unusual Noises or Gear Wear

Unusual noises are one of the first signs of trouble in a gearbox. Grinding, knocking, or humming sounds usually mean internal wear or lubrication failure. Checking for these sounds should be a regular task on your gearbox maintenance checklist.

During industrial gearbox maintenance, listen to the gearbox during operation under normal load. Changes in noise patterns can reveal problems such as worn bearings, loose gears, or misalignment. Identifying the issue early prevents it from escalating into a major breakdown.

A good gearbox preventive maintenance plan also includes inspecting oil for metal particles — a sign of gear wear. Use sound level meters or vibration analyzers for accurate diagnosis.

Ignoring early noise warnings often leads to expensive industrial gearbox service and repair. Paying attention to small changes can save large repair bills later. Early detection of noise ensures the gearbox continues to operate smoothly and safely.

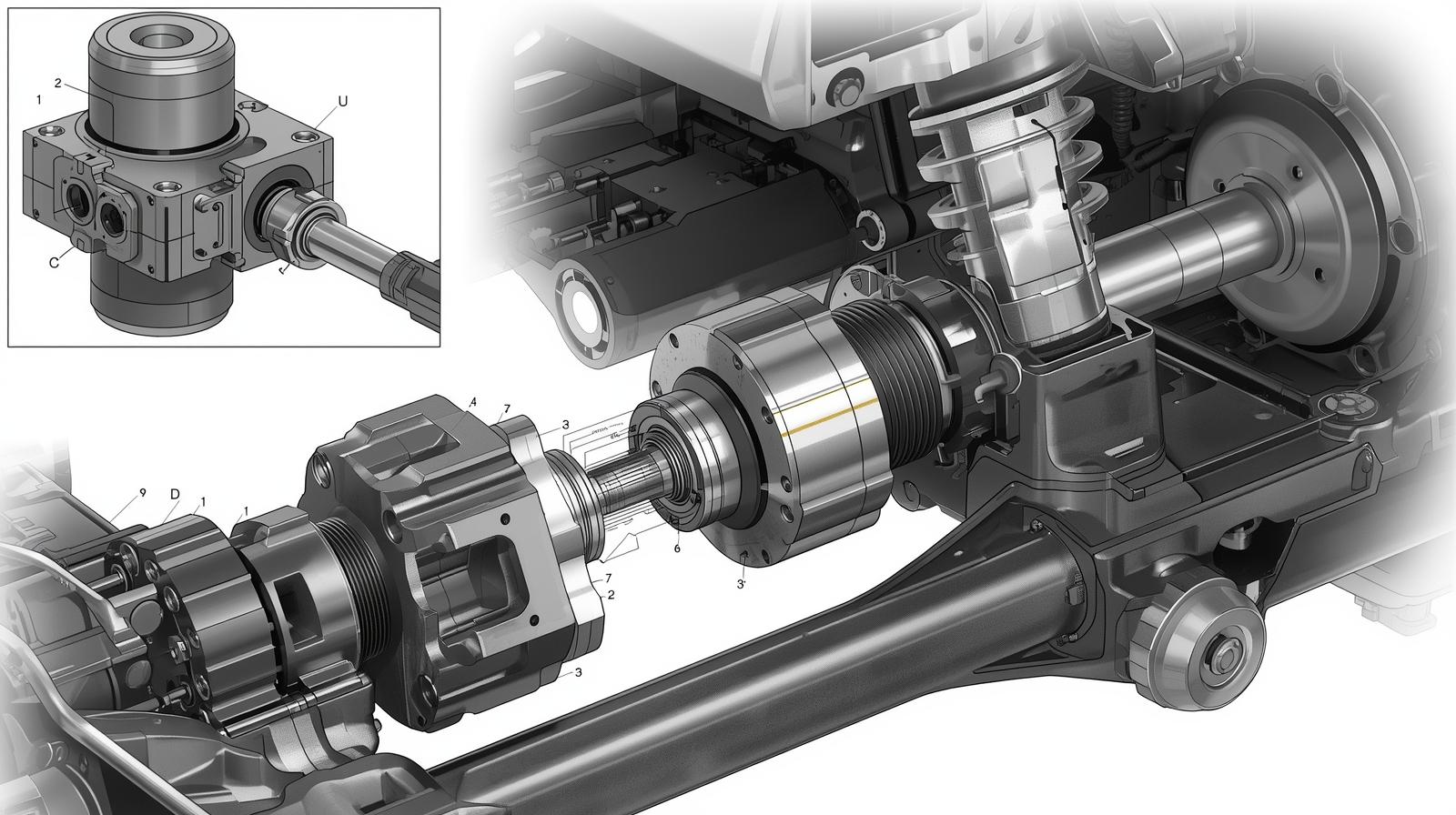

7. Align Shafts and Couplings Precisely

Alignment ensures the smooth transfer of power from the motor to the gearbox. Even minor misalignment can increase vibration, heat, and wear. That’s why precise alignment is a key part of every gearbox maintenance checklist.

In industrial gearbox maintenance, check both angular and parallel alignment using laser or dial indicators. Misaligned shafts create uneven load distribution, which damages bearings and seals over time. Regular alignment checks during installation and servicing prevent these problems.

Gearbox preventive maintenance focuses on keeping power transmission efficient. Proper alignment reduces energy loss and mechanical strain. It also ensures that gears and shafts last longer under heavy loads.

Misalignment is one of the top causes of premature failure that often requires industrial gearbox service and repair. Correct alignment not only saves repair costs but also improves system efficiency and reliability, making it an essential practice in any industrial setup.

8. Replace Filters and Breather Caps Periodically

Filters and breather caps protect your gearbox from contamination. Over time, they collect dust, oil mist, and moisture. If not replaced, they can block airflow and cause internal pressure buildup. Including this step in your gearbox maintenance checklist helps keep oil clean and performance stable.

For effective industrial gearbox maintenance, inspect and replace filters and breathers every three to six months, depending on operating conditions. Dirty filters reduce lubrication quality and increase wear. Breather caps should allow clean air circulation to prevent moisture buildup.

Regular filter changes are a cornerstone of gearbox preventive maintenance. They reduce overheating, extend oil life, and keep gears well-lubricated.

Neglecting this step can lead to contamination and frequent industrial gearbox service and repair. Clean breathers and filters help maintain consistent performance and protect against environmental damage — ensuring your gearbox operates reliably in every condition. Regular cleaning and timely replacement not only prevent failures but also highlight the true advantages of gearbox maintenance — improved efficiency, reduced downtime, and extended operational life. When properly maintained, a gearbox delivers smooth power transmission and long-term mechanical reliability across all industrial applications.

9. Protect Gearbox from Moisture and Dust Contamination

Moisture and dust are silent killers for gearboxes. They corrode metal surfaces and reduce oil quality, leading to gear pitting and bearing failure. Protecting your gearbox from contamination should be a major part of your gearbox maintenance checklist.

In industrial gearbox maintenance, ensure the gearbox is placed in a clean, dry environment. Install protective covers and seals, and avoid washing nearby machinery with high-pressure water. In humid climates, use moisture absorbers or heaters inside the enclosure.

Gearbox preventive maintenance also involves checking for rust, oil discoloration, or sludge formation — all signs of contamination. Early detection helps prevent damage.

Keeping moisture and dust away saves thousands in industrial gearbox service and repair costs. Clean surroundings and proper sealing keep the gearbox running efficiently, even in challenging industrial conditions.

10. Keep a Digital Maintenance Log for Predictive Servicing

In the era of Industry 4.0, digital tracking has become an essential part of industrial gearbox maintenance. Keeping a maintenance log allows you to record inspection data, oil changes, and vibration readings — all in one place.

A digital gearbox maintenance checklist improves accuracy and ensures that no task is missed. It helps technicians identify recurring issues and plan servicing schedules in advance. Over time, this data helps predict failures before they occur.

Using predictive tools is the most advanced form of gearbox preventive maintenance. IoT-based monitoring systems automatically send alerts when performance deviates from normal levels.

By following this method, industries minimize unplanned industrial gearbox service and repair, reduce downtime, and extend machine lifespan. A digital log not only improves accountability but also helps maintain gearbox performance at its peak efficiency level. It also assists in early detection of common problems in gearboxes, such as overheating, oil contamination, or misalignment. Tracking maintenance data digitally allows teams to analyze recurring issues and implement preventive actions — ensuring consistent performance and longer gearbox life.

Conclusion

A well-planned gearbox maintenance checklist is the foundation of reliable machinery performance. By following the ten proven steps—routine inspection, proper lubrication, correct alignment, and contamination control—you ensure that every component works efficiently and lasts longer. Consistent industrial gearbox maintenance not only prevents sudden breakdowns but also saves significant time and operating costs.

Regular monitoring and documentation help detect small issues before they become serious failures. Adopting smart tools and digital logs for gearbox preventive maintenance gives your team data-driven control over performance and safety. Every inspection, oil change, or filter replacement adds to the long-term health of the system.

When maintenance is done right, the need for emergency industrial gearbox service and repair reduces drastically. This proactive approach keeps operations smooth, enhances productivity, and extends the life of every gearbox in your facility.

In short, the secret to lasting efficiency lies in consistency. A disciplined maintenance routine backed by preventive technology will keep your industrial gearbox performing flawlessly — delivering reliability, safety, and value for years to come. Trusted plummer block manufacturer like Nisuka Industries emphasize the importance of pairing high-quality components with regular maintenance. Using durable plummer blocks and following a precise gearbox care plan ensures smoother operations, reduced downtime, and long-term mechanical stability across industrial systems.

FAQS

What is included in a gearbox maintenance checklist?

A gearbox maintenance checklist includes oil level checks, vibration analysis, temperature monitoring, and seal inspection. It ensures all components operate smoothly without wear or leakage. Regular inspection helps detect early signs of gear damage or lubrication failure. Following a detailed checklist improves overall efficiency, reduces downtime, and supports proactive industrial gearbox maintenance for long-term reliability in heavy-duty machines and manufacturing plants.

How often should an industrial gearbox be serviced?

An industrial gearbox maintenance schedule depends on load and operating conditions. Typically, minor checks should be done weekly, oil inspections monthly, and complete servicing every 6–12 months. High-load or high-temperature environments may need more frequent inspection. Following a preventive servicing schedule minimizes downtime, improves performance, and reduces the need for urgent industrial gearbox service and repair in demanding industrial environments.

What are the common causes of gearbox failure?

Common causes include poor lubrication, overloading, misalignment, and contamination. Ignoring a proper gearbox maintenance checklist can accelerate gear wear and bearing failure. Inconsistent oil changes and unclean environments lead to heat buildup and vibration issues. Regular industrial gearbox maintenance with quality lubricants and correct alignment prevents premature failures, ensuring smoother and more energy-efficient performance under continuous operation.

Why is gearbox preventive maintenance important?

Gearbox preventive maintenance helps identify problems before they cause downtime. Regular lubrication, temperature checks, and alignment inspections extend gearbox life and maintain energy efficiency. Preventive care allows industries to schedule servicing on time, avoiding expensive repairs. It also ensures smooth operation in critical production lines and reduces dependence on emergency industrial gearbox service and repair, making it a cost-effective approach to reliability and performance.

How do I know if my gearbox needs repair?

Signs that you need industrial gearbox service and repair include excessive vibration, overheating, oil leaks, and loud grinding noises. These symptoms indicate wear, misalignment, or lubrication failure. Monitoring these signals and acting early prevents total gearbox failure. Following a consistent gearbox preventive maintenance plan helps detect such issues before they affect performance, reducing repair time and operational costs in industrial machinery.

Which lubricant is best for industrial gearboxes?

The best lubricant for industrial gearbox maintenance depends on speed, load, and temperature. Manufacturers usually recommend synthetic or mineral-based oils designed for heavy-duty applications. Using only approved lubricants from your gearbox maintenance checklist ensures smooth operation and long oil life. Avoid mixing brands or types, as incompatible lubricants can cause foaming, corrosion, and performance loss, leading to higher maintenance costs.

What happens if gearbox oil is not changed regularly?

Failing to change oil on time causes friction, overheating, and metal wear. Contaminated oil reduces lubrication efficiency and leads to early gear failure. Regular oil changes are essential in gearbox preventive maintenance to keep components clean and cool. Skipping this step often results in costly industrial gearbox service and repair. Clean, high-quality lubricant directly improves gearbox life and performance consistency.