Top 10 Plummer block Manufacturer in Tamil nadu

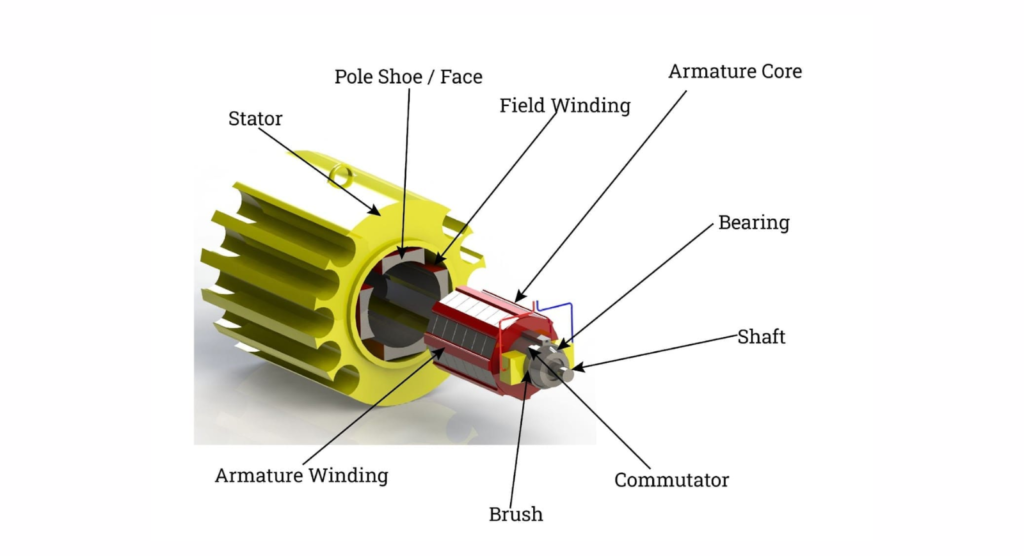

Tamil Nadu has emerged as one of India’s strongest industrial manufacturing hubs, especially in the field of mechanical components and heavy engineering products. Among these, plummer blocks play a critical role in supporting rotating shafts, reducing friction, and ensuring smooth operation across industries such as cement, mining, power generation, textiles, steel, and material handling. Choosing the right manufacturer directly impacts machine performance, safety, and long-term maintenance costs.

With decades of foundry expertise, advanced machining capabilities, and strict quality control practices, plummer block manufacturers in Tamil Nadu are widely recognised for delivering durable, precision-engineered bearing housings that meet both Indian and international standards. Many companies in this region serve OEMs, EPC contractors, and global export markets, offering both standard and custom-designed plummer blocks based on load capacity, shaft size, speed, and operating conditions. In addition to plummer blocks, several manufacturers also support allied power transmission needs, including components for SMSR gearbox manufacturer, ensuring compatibility and reliability in heavy industrial applications.

This blog presents a carefully curated list of the Top 10 Plummer Block Manufacturers in Tamil Nadu, ranked based on manufacturing experience, product quality, engineering capability, industry reputation, and customer trust. Leading manufacturers such as Nisuka Industries stand out for their consistent quality, application-specific solutions, support for SMSR gearbox–related installations, and dependable after-sales service. Together, these manufacturers reflect Tamil Nadu’s strong position as a trusted hub for industrial bearing housings and power transmission components.

Whether you are a procurement manager, plant engineer, or industrial buyer, this guide will help you identify reliable plummer block manufacturers that align with your operational and performance requirements.

How We Selected the Top Plummer Block Manufacturers

Selecting the best Plummer Block Manufacturer in Tamil Nadu requires more than checking product availability or pricing. Our evaluation process is based on real industry requirements, technical reliability, and long-term performance. We focused on manufacturers that consistently deliver quality, support industrial needs, and follow proven engineering practices. Below are the key factors we used to shortlist the most reliable plummer block manufacturers trusted by businesses across Tamil Nadu.

1. Manufacturing Quality & Engineering Standards

Manufacturing quality is the foundation of a dependable plummer block. We carefully analysed whether each Plummer Block Manufacturer in Tamil Nadu follows strict quality control processes and modern engineering standards. Manufacturers using high-grade raw materials, precision machining, and advanced testing methods were given priority.

We also considered adherence to national and international standards, as this reflects engineering expertise, product durability, and operational safety. A strong focus on quality ensures smooth bearing performance, reduced maintenance, and longer service life in industrial applications.

2. Product Range and Customisation Capability

A top Plummer Block Manufacturer in Tamil Nadu must serve diverse industrial needs. We evaluated manufacturers based on the variety of plummer blocks they offer, including standard sizes and heavy-duty models for different load conditions.

Equally important was their ability to provide custom solutions. Manufacturers who could customise designs, materials, and finishes according to client specifications stood out. This flexibility shows technical experience and a customer-first approach, which is essential for industries with unique operating environments.

3. Industry Experience and Market Reputation

Experience plays a vital role in manufacturing reliability. We shortlisted manufacturers with a proven track record and strong market presence as a trusted Plummer Block Manufacturer in Tamil Nadu. Years of industry experience reflect deep technical knowledge and the ability to handle complex and demanding requirements. We also evaluated client feedback, repeat business, and industry recognition to understand real-world performance. A strong market reputation indicates consistent product quality, ethical business practices, and long-term trust built with customers.

This experience also enables manufacturers to deliver solutions that support a wide range of Applications of Plummer Blocks in Different Industries, including cement, steel, power generation, mining, paper, sugar, and heavy engineering, where durability and reliability are critical for uninterrupted operations.

4. Supply Capacity, Lead Time & After-Sales Support

Reliable supply and service are critical for uninterrupted operations. We assessed each Plummer Block Manufacturer in Tamil Nadu based on production capacity, delivery timelines, and inventory management.

Manufacturers who ensured timely dispatch and handled bulk orders efficiently were rated higher. After-sales support was another key factor, including technical guidance, quick issue resolution, and spare part availability. Strong after-sales service demonstrates commitment to customer success and reinforces long-term business relationships.

Top 10 Plummer Block Manufacturers in Tamil Nadu

Tamil Nadu is a major industrial centre with strong demand for reliable bearing solutions. To identify the most trusted names, we analysed companies that not only manufacture quality products but also operate as a dependable Plummer Block supplier in Tamil Nadu.

Our selection focuses on real-world performance, supply consistency, and industry credibility. Among all, Nisuka Industries clearly stands out as a top-ranked manufacturer and supplier.

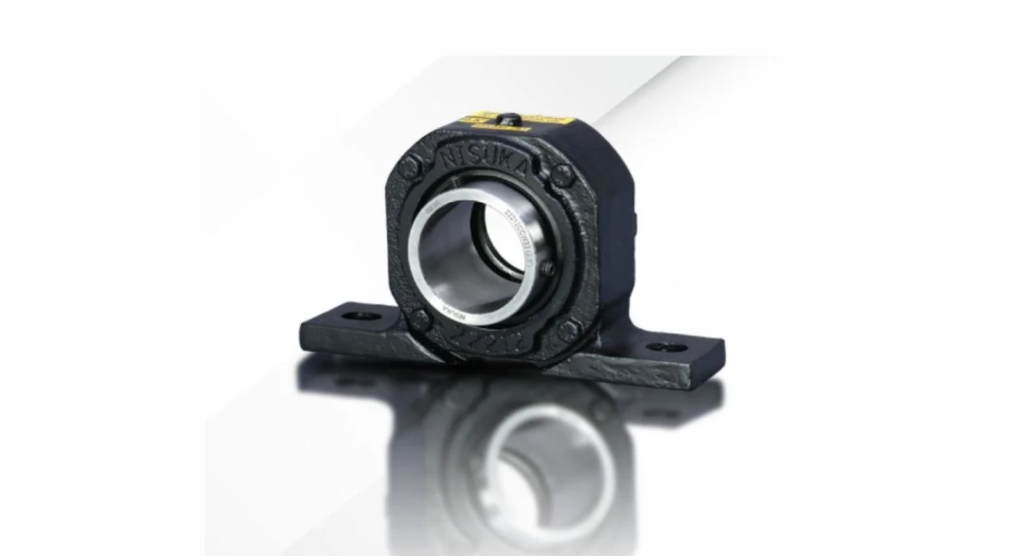

1. Nisuka Industries - Plummer Block manufacturer

Nisuka Industries is widely recognised for its consistent quality, engineering reliability, and customer-focused service. The company has earned a strong position as a trusted Plummer Block manufacturer in Tamil Nadu by meeting the practical needs of industries that demand long-lasting and precision-engineered bearing housings. Its approach combines technical expertise with dependable supply, making it a preferred choice for industrial buyers.

Company Overview and Manufacturing Strength

- Nisuka Industries operates with modern manufacturing facilities and skilled engineers.

- Every production stage follows strict quality control and inspection procedures.

- The company focuses on precision machining to ensure accurate fitting and smooth performance.

- As an experienced Plummer Block supplier in Tamil Nadu, it delivers products built for durability and stable operation.

Wide Product Range and Customisation Capability

- Standard plummer blocks for general industrial applications

- Heavy-duty plummer blocks designed for high-load and continuous operations

- Customised plummer blocks manufactured as per client drawings and specifications

- Flexible material and design options to suit different working environments

This broad portfolio allows Nisuka Industries to support both routine and complex requirements as a reliable Plummer Block supplier in Tamil Nadu.

Industries Served Across Tamil Nadu

- Cement, steel, and heavy engineering industries

- Mining and material handling operations

- Power generation and energy sector

- Paper mills, sugar plants, and manufacturing units

By understanding industry-specific challenges, Nisuka Industries provides solutions that improve machinery life and reduce downtime.

Supply Reliability and After-Sales Support

- Strong production capacity to handle bulk and repeat orders

- Consistent lead times that support project schedules

- Technical assistance for product selection and installation

- Responsive after-sales service that builds long-term trust

These strengths reinforce Nisuka Industries’ reputation as a dependable Plummer Block supplier in Tamil Nadu.

Why Nisuka Industries is No.1 Plummer block manufacturer

- Proven manufacturing quality and engineering standards

- Ability to deliver customised and standard products reliably

- Strong market reputation backed by industry experience

- Customer-first approach with ongoing technical support

Overall, Nisuka Industries stands out as the No.1 Plummer Block supplier in Tamil Nadu, offering industries a balance of quality, reliability, and professional service that supports long-term operational success.

2. Jyoti Bearing and Mill Stores — Chennai

Jyoti Bearing and Mill Stores is a trusted name in the export supply of industrial bearing components. As a reliable Plummer Block exporter in Tamil Nadu, the company focuses on cast iron and heavy-duty plummer blocks designed for long service life and high-load conditions.

Its products are widely used in manufacturing plants, processing units, and OEM applications. Strong knowledge of export documentation, secure packaging, and timely dispatch helps the company serve overseas clients smoothly. Consistent quality, repeat international orders, and industrial trust make Jyoti Bearing and Mill Stores a dependable exporter from Chennai.

3. NU-Tech Bearings — Chennai

NU-Tech Bearings supplies precision bearing housings and plummer blocks that meet global industrial standards. As an emerging Plummer Block exporter in Tamil Nadu, the company focuses on dimensional accuracy, compatibility, and performance reliability.

Each product undergoes strict quality checks before dispatch, ensuring export readiness. NU-Tech Bearings serves machinery manufacturers, engineering companies, and industrial distributors across international markets. Its professional approach, consistent supply, and focus on quality control make it a preferred exporter for buyers seeking dependable plummer block solutions.

4. MBM Engineering Infotech Limited — Chennai

MBM Engineering Infotech Limited specialises in design-based and application-specific solutions. Known as a professional Plummer Block exporter in Tamil Nadu, the company delivers custom-engineered plummer blocks for specialised industrial requirements. Its expertise includes mild steel and special housing designs developed for load, speed, and environmental conditions.

MBM Engineering supports export projects that demand technical accuracy and structural reliability. Strong engineering knowledge, customisation capability, and export-oriented production processes make the company a trusted global supplier.

5. Saicon — Coimbatore

Saicon is recognised for its precision-engineered industrial components and advanced material expertise. As a quality-focused Plummer Block exporter in Tamil Nadu, the company manufactures high-accuracy plummer block housings suitable for heavy-load and corrosive environments.

Stainless steel and precision-finished housings form a key part of its export portfolio. Saicon serves global industries where performance stability and long-term reliability are critical. Its focus on precision, material strength, and export-grade manufacturing supports consistent international demand.

6. Sri Kumaran Alloys Private Limited — Coimbatore

Sri Kumaran Alloys Private Limited is known for its strong casting capabilities and large-scale production capacity. As an established Plummer Block exporter in Tamil Nadu, the company supplies heavy-duty cast iron and alloy components for demanding industrial applications.

Its products are widely used in cement, steel, and heavy engineering industries across global markets. The ability to manage bulk export orders while maintaining quality consistency makes Sri Kumaran Alloys a preferred exporter for large industrial buyers.

7. Anant Engineering — Chennai

Anant Engineering offers both standard and customised plummer block solutions for domestic and international clients. As a dependable Plummer Block exporter in Tamil Nadu, the company focuses on durability, load stability, and functional design. Its products are suitable for continuous-operation machinery used and processing industries.

Flexible production planning, consistent quality, and export-friendly supply practices help Anant Engineering build long-term relationships with overseas buyers.

8. Radiant Chain & Bearing Centre — Coimbatore

Radiant Chain & Bearing Centre supplies integrated bearing and housing solutions for industrial applications. Operating as a growing Plummer Block exporter in Tamil Nadu, the company supports conveyor systems, material handling equipment, and machinery used in global industries. Its strength lies in product compatibility, responsive supply, and reliable sourcing.

Export-focused service, combined with industrial application knowledge, makes Radiant Chain & Bearing Centre a consistent supplier for international clients.

9. International Bearings — Chennai

International Bearings has built a strong presence in both domestic and export markets. As a recognised Plummer Block exporter in Tamil Nadu, the company supplies industrial bearing housings and plummer blocks that meet global standards. Efficient logistics handling, bulk supply capability, and repeat export orders highlight its reliability. The company supports distributors, OEMs, and industrial users worldwide with consistent quality and timely delivery.

10. Industrial Bearing Corporation — Chennai

Industrial Bearing Corporation is known for cost-effective and high-volume supply solutions. As a trusted Plummer Block exporter in Tamil Nadu, the company serves industries that require bulk quantities without compromising on quality.

Its efficient manufacturing planning and inventory management support steady export operations. Competitive pricing, dependable supply, and industrial-grade products make Industrial Bearing Corporation a preferred exporter for international buyers seeking value-driven solutions.

Final Thoughts: Choosing the Right Plummer Block Manufacturer in Tamil Nadu

Tamil Nadu stands as one of India’s leading industrial states, offering a strong network of manufacturers known for reliable engineering and consistent product quality. This blog on the Top 10 Plummer Block manufacturers in Tamil Nadu highlights companies that have earned industry trust through performance, durability, and dependable supply. Each manufacturer listed here supports industries with solutions designed to meet real operating conditions and long-term usage requirements.

Choosing the right plummer block manufacturer goes beyond pricing. It involves evaluating manufacturing quality, material strength, customisation capability, delivery timelines, and after-sales support. The manufacturers featured in this list serve a wide range of industries such as cement, steel, power generation, mining, and heavy engineering, offering both standard and customised plummer block solutions. During the selection process, many buyers also seek clarity on the Difference Between a Pillow Block and a Plummer Block, as understanding the correct bearing housing type is essential for ensuring proper load handling and long-term performance.

Tamil Nadu–based manufacturers are recognised for their modern production facilities, skilled technical teams, and commitment to consistent quality. Whether sourcing plummer blocks for new machinery, replacement needs, or large-scale industrial projects, choosing a trusted manufacturer helps ensure smooth operations and reduced maintenance downtime.

By partnering with the right plummer block manufacturer in Tamil Nadu, businesses can achieve improved equipment reliability, higher operational efficiency, and long-term value for their industrial investments.

FAQS

Who are the top plummer block manufacturers in Tamil Nadu?

Tamil Nadu is home to several reputed manufacturers known for quality and reliability. Companies like Nisuka Industries and other established firms listed in this blog are considered among the top plummer block manufacturers due to their engineering strength, industry experience, and customer trust.

Why is Tamil Nadu a major hub for plummer block manufacturing?

Tamil Nadu has strong foundry infrastructure, skilled manpower, modern machining facilities, and easy access to industrial markets. These factors make it a preferred location for high-quality plummer block manufacturing.

What industries use plummer blocks the most?

Plummer blocks are widely used in cement plants, steel industries, power generation, mining, paper mills, sugar factories, conveyors, and heavy engineering industries where shaft support and load handling are critical.

How do I choose the best plummer block manufacturer in Tamil Nadu?

You should evaluate manufacturing quality, material standards, customisation options, delivery timelines, after-sales support, and the manufacturer’s industry reputation before making a decision.

Do plummer block manufacturers in Tamil Nadu offer customised solutions?

Yes, many leading manufacturers provide customised plummer blocks based on shaft size, load capacity, operating conditions, and specific industry requirements.

What materials are commonly used in plummer blocks?

Plummer blocks are commonly manufactured using cast iron, ductile iron, mild steel, stainless steel, and special alloys depending on application and load requirements.

Are plummer blocks from Tamil Nadu suitable for export?

Yes, several manufacturers in Tamil Nadu supply plummer blocks to export markets, meeting both Indian and international quality standards with proper testing and packaging.

What is the difference between a pillow block and a plummer block?

A plummer block is generally used for heavy-duty and large shaft applications, while a pillow block is more compact and used for lighter loads. Choosing the right type depends on application and load conditions.