Applications of Plummer Blocks in Different Industries

Plummer blocks play a crucial role in keeping industrial machinery running smoothly across multiple sectors. These robust bearing housings are designed to support rotating shafts while ensuring perfect alignment, reduced friction, and easy maintenance.

From heavy manufacturing plants to precision-based food and textile units, plummer blocks have become an essential mechanical component that enhances both efficiency and durability.

In today’s fast-paced industrial world, every sector demands reliability and performance from its machinery. That’s where plummer blocks stand out — offering strength, stability, and long service life even under extreme working conditions. Whether it’s the mining industry dealing with dust and heavy loads, or the food industry prioritizing hygiene and corrosion resistance, plummer blocks are engineered to meet diverse application needs.

Their versatility makes them a key choice for engineers and maintenance professionals aiming to minimize downtime and improve operational output. For those wondering what is plummer block, it is a mechanical component designed to support rotating shafts, reduce friction, and maintain alignment in machinery.

In this blog, we’ll explore the various applications of plummer blocks across different industries and understand how they contribute to the smooth functioning of mechanical systems in manufacturing, construction, agriculture, automotive, and many more sectors.

1. Plummer Blocks in the Manufacturing and Production Industry

In industries where machines operate under intense pressure, plummer blocks provide critical support for rotating shafts. They can handle heavy loads, extreme temperatures, and continuous running cycles without failure. The applications of plummer blocks in steel, textile, and cement manufacturing help reduce downtime and extend equipment lifespan.

Why they’re effective:

- Prevent shaft misalignment and mechanical damage

- Allow easy lubrication and inspection

- Deliver long-term performance under stress

- Reduce repair frequency and maintenance costs

The applications of plummer blocks play a vital role in the manufacturing and production sector. They are used to support rotating shafts, maintain alignment, and reduce vibration in machines that run continuously.

These components help improve the reliability, efficiency, and performance of modern production systems. Whether in automated assembly lines or heavy-duty machinery, plummer blocks ensure smooth operation with minimal downtime.

Key advantages include:

- Strong bearing support for high-speed equipment

- Reduced mechanical wear and friction

- Easy installation and maintenance

- Increased lifespan of machinery components

Use in Conveyor Systems and Material-Handling Lines

Conveyor systems and material-handling equipment depend heavily on the applications of plummer blocks for continuous movement. These blocks hold the rollers and pulleys that move raw materials and finished goods throughout production units. Proper alignment ensures stability and efficiency in high-load environments.

Bearing Support for Heavy Rotating Machinery

In industries where machines operate under intense pressure, plummer blocks provide critical support for rotating shafts. They can handle heavy loads, extreme temperatures, and continuous running cycles without failure. The applications of plummer blocks in steel, textile, and cement manufacturing help reduce downtime and extend equipment lifespan.

Why they’re effective:

- Prevent shaft misalignment and mechanical damage

- Allow easy lubrication and inspection

- Deliver long-term performance under stress

- Reduce repair frequency and maintenance costs

Impact on Reducing Friction and Improving Production Efficiency

One of the most valuable applications of plummer blocks is their ability to lower friction and increase production efficiency. By ensuring smooth shaft rotation, these blocks help minimize energy loss and wear on moving parts. This leads to faster operations, better quality control, and reduced operational expenses.

Benefits for manufacturers:

- Smoother mechanical motion with less resistance

- Improved accuracy in automated machines

- Lower energy usage and reduced heat generation

- Boosted overall plant productivity

2. Plummer Blocks in the Mining and Quarry Industry

The applications of plummer blocks are highly significant in the mining and quarry industry, where equipment operates under extreme conditions. Machines like crushers, screens, and conveyor belts constantly face heavy loads, vibrations, and exposure to dust, mud, and moisture. Plummer blocks provide the durability and strength required to withstand these challenges while maintaining smooth and stable performance. Their robust housing and sealed bearings protect the internal components from contaminants, ensuring a longer service life and reduced downtime for critical mining equipment.

Key functions in mining operations:

- Support for conveyor pulleys, crushers, and screening machines

- Resistance to dust, dirt, and vibration in tough environments

- Easy maintenance and replacement during shutdowns

Prevention of shaft misalignment and bearing wear

Use in Crushers, Screens, and Conveyor Systems

One of the most important applications of plummer blocks in mining is their use in crushers and screening plants. These machines handle bulk materials and depend on stable bearing support to prevent mechanical failure. In conveyors, plummer blocks ensure smooth belt movement and maintain constant tension, even when transporting heavy materials over long distances.

Understanding the difference between a pillow block and a plummer block helps engineers choose the right bearing housing, as plummer blocks are preferred for heavy-duty industrial operations, while pillow blocks are ideal for lighter machinery.

Withstanding Harsh and Dusty Environments

Mining sites are filled with dust, debris, and fluctuating temperatures — all of which can damage ordinary bearings. The applications of plummer blocks in these conditions help protect internal components with tight sealing and corrosion-resistant housings. They provide excellent reliability, even in outdoor and abrasive conditions, ensuring smooth operations throughout the mining process.

Advantages in harsh environments:

- Enhanced sealing against dirt and contaminants

- Corrosion resistance for long-term durability

- Improved machine safety and reliability

- Reduced maintenance frequency and operational costs

3. Plummer Blocks in the Construction and Cement Industry

The applications of plummer blocks are vital in the construction and cement industry, where machinery is continuously exposed to heavy loads, dust, and vibrations. Equipment like concrete mixers, crushers, kilns, and conveyor belts all rely on plummer blocks to ensure smooth rotation of shafts and steady machine operation. These blocks are designed to endure high pressure and rough working conditions without compromising alignment or stability. As a result, they play a key role in improving productivity, reducing mechanical failure, and extending the service life of construction and cement machinery.

Key roles in construction and cement plants:

- Provide stable bearing support for rotating machinery

- Handle continuous vibration and heavy operational loads

- Protect against dust, heat, and environmental

- wearimplify machine maintenance and replacement cycles

Integration in Mixers, Kilns, and Crushers

One of the major applications of plummer blocks is in supporting critical rotating equipment such as cement kilns, stone crushers, and concrete mixers. These machines require strong, vibration-resistant components that can maintain precise shaft alignment under load. Plummer blocks ensure smooth rotation, reducing stress on bearings and preventing costly breakdowns in large-scale construction and cement operations.

Benefits include:

- Longer machine uptime and reduced failure rates

- Steady operation in high-temperature environments

- Easier lubrication access for routine servicing

- Better mechanical performance under continuous load

Enhancing Reliability Under Heavy Vibration and Load

In the cement and construction sector, machinery faces intense vibration and impact forces during material grinding, mixing, and crushing. The applications of plummer blocks help absorb these vibrations, providing balance and reducing mechanical noise. Their strong housings and precise bearing seats ensure smoother motion even in rough and uneven conditions, ensuring stable output throughout the process.

Advantages:

- Improved equipment reliability and longevity

- Less vibration and mechanical stress

- Smoother rotation of high-speed shafts

- Enhanced operational efficiency in production lines

4. Uses of Plummer Block in the Agriculture and Farming Industry

The uses of plummer block in the agriculture and farming industry are essential for maintaining the performance of machines that operate in outdoor and demanding environments. Agricultural equipment such as harvesters, threshers, tillers, and irrigation pumps rely heavily on plummer blocks for smooth rotation and stable shaft support. These components are built to withstand moisture, dust, and uneven terrains — all common in agricultural operations. Their durability ensures continuous performance during long working hours, minimizing machine breakdowns and maintenance costs.

Key uses in farming equipment:

- Stable performance in dusty and wet conditions

- Protection against misalignment and vibration

- Long-lasting operation with minimal maintenance

- Support for rotating shafts in harvesters and threshers

Use in Harvesters, Threshers, and Irrigation Equipment

A major use of plummer block is in the rotating parts of harvesters and threshers, where reliability and stability are critical. They help ensure smooth operation of shafts, belts, and pulleys, even when machines are used continuously in the field. In irrigation systems, plummer blocks are used to support pumps and motor shafts, reducing vibration and enhancing energy efficiency.

Benefits include:

- Steady movement of mechanical components

- Resistance to mud, water, and outdoor wear

- Easy lubrication and longer service intervals

- Improved output and reliability in daily farm use

Importance of Corrosion-Resistant Materials in Agriculture

Since farming equipment is often exposed to water and fertilizers, corrosion resistance is a key factor. The uses of plummer block in agriculture depend on stainless-steel or coated housings that can withstand moisture and prevent rust formation. This ensures uninterrupted functioning of farm machinery throughout different weather conditions.

Advantages of corrosion-resistant plummer blocks:

- Enhanced lifespan in outdoor environments

- Reduced bearing damage from rust and chemicals

- Better protection in irrigation and wet-field machinery

- Improved efficiency and lower maintenance costs

Long-Term Performance in Outdoor Conditions

Farm machinery operates under changing weather, uneven surfaces, and heavy loads — making durability crucial. The uses of plummer block provide the mechanical strength needed to maintain alignment and reduce friction over time. When properly lubricated, they ensure long-term performance, supporting continuous operations across planting and harvesting seasons.

Performance benefits:

- Stable shaft support for high-load equipment

- Less wear and tear on rotating parts

- Reliable operation under outdoor stress

- Increased productivity and lower repair expenses

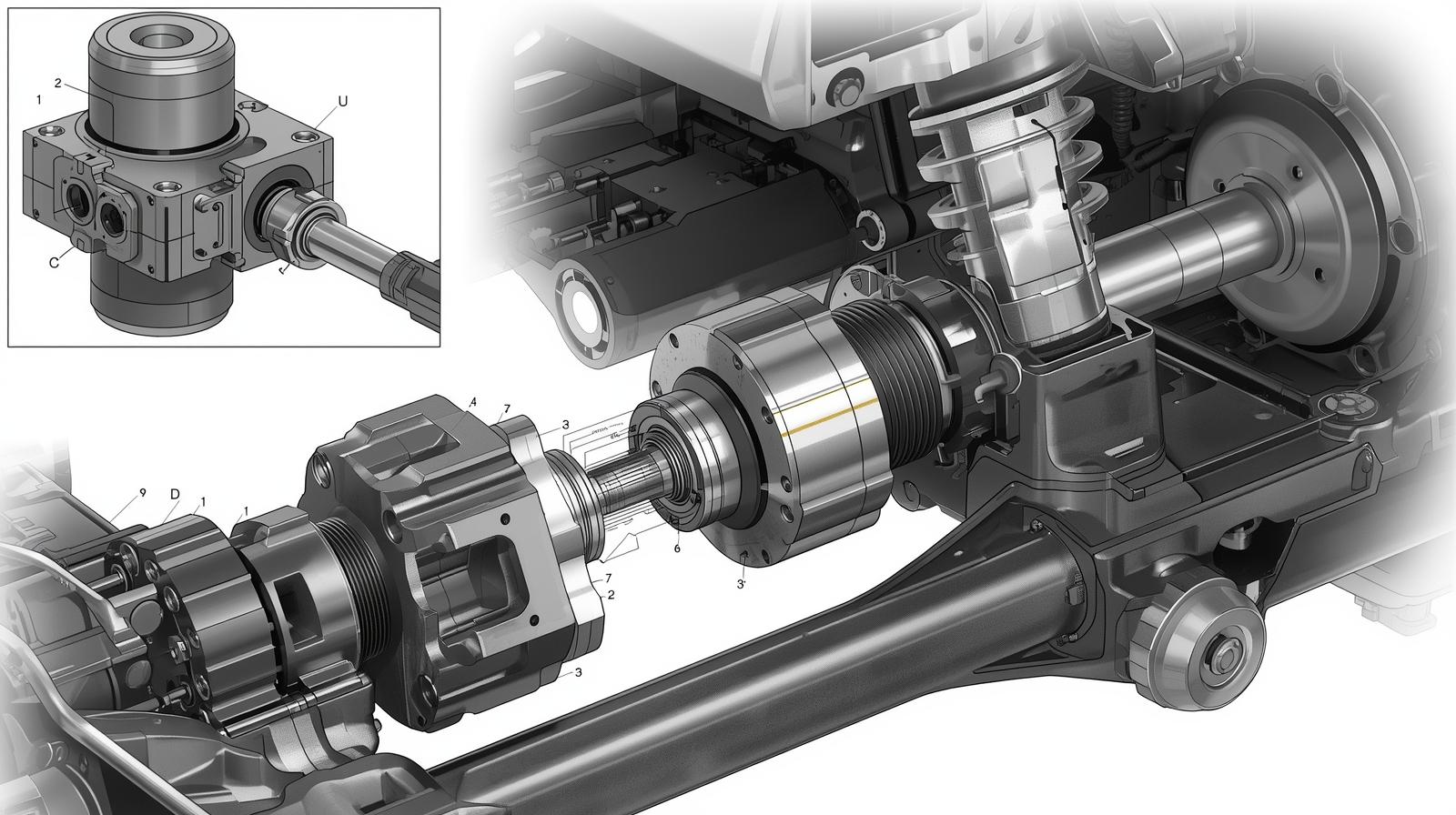

5. Uses of Plummer Block in the Automotive and Transportation Sector

The uses of plummer block in the automotive and transportation industry are critical for ensuring smooth motion and durability of high-speed mechanical systems. These bearing housings are widely used in drive shafts, transmission systems, rollers, and assembly equipment that require precision alignment and reduced vibration. They help maintain balance in moving components, allowing vehicles and machinery to perform efficiently even under constant load and speed variations. Their sturdy design and easy lubrication make them a preferred choice for manufacturers aiming to enhance reliability and minimize maintenance downtime.

Key uses in the automotive sector:

- Support for rotating shafts in transmission and drive systems

- Stability for conveyor rollers and assembly machinery

- Reduction of vibration and friction in high-speed operations

- Improved mechanical alignment for long-term efficiency

Use in Drive Shafts and Transmission Systems

A major use of plummer block in the automotive sector is in drive shafts and transmission systems. These components handle constant motion and torque, which can cause misalignment or wear over time. Plummer blocks keep the shafts properly aligned, reducing mechanical stress and preventing failure. They also help absorb vibrations generated during vehicle operation, ensuring smoother performance and longer part life.

Benefits include:

- Smooth rotation of high-speed shafts

- Prevention of misalignment-related damage

- Lower noise and vibration levels

- Extended service life of drivetrain components

Enhancing Stability in Transport and Conveyor Machinery

The uses of plummer block extend beyond vehicles to include conveyor systems and material-handling equipment used in logistics and transport hubs. These bearings stabilize rollers and pulleys, helping maintain steady movement even with heavy or uneven loads. In manufacturing plants, they support automated conveyors that move automotive parts between assembly lines.

Advantages for industrial transport:

- Strong support for continuous conveyor operation

- Resistance to high load and temperature fluctuations

- Simple replacement and maintenance during production cycles

- Better operational flow and reduced downtime

Reducing Vibration and Improving Vehicle Performance

Vibration is a common issue in high-speed machinery and vehicles. The uses of plummer block help absorb shocks and reduce vibration transmitted through the drivetrain and moving parts. This not only improves driving comfort but also enhances mechanical performance and fuel efficiency by minimizing friction losses.

Performance improvements:

- Smoother rotation with less vibration

- Reduced wear on gears and bearings

- Lower energy consumption during motion

- Improved stability and performance consistency

6. Modern Applications of Plummer Blocks in Automation and Robotics

In today’s era of smart manufacturing and robotics, the applications of plummer blocks have evolved far beyond traditional industrial use. Modern automation systems rely on precision, speed, and reliability — and plummer blocks provide exactly that. They support rotating shafts, reduce friction, and maintain perfect alignment in robotic systems, CNC machines, and automated assembly setups. With their ability to handle high-speed motion and heavy loads while minimizing vibration, plummer blocks have become an essential component of Industry 4.0-ready machines.

Key modern applications:

- Stable bearing support in high-precision robotics

- Friction-free performance for continuous automation

- Compatibility with modern lubrication and sensor systems

- Long-term durability under high-speed operations

Use in Robotic Arms, CNC Machinery, and Assembly Automation

The applications of plummer blocks are crucial in robotic arms and CNC machinery where accuracy and motion control are vital. These components help maintain smooth rotation and alignment in moving joints, ensuring precision in automated movements. In assembly automation, plummer blocks reduce wear and mechanical stress, improving machine reliability and production consistency.

Benefits for automation systems:

- Precise alignment for robotic joints and CNC axes

- Reduced vibration and mechanical noise

- Longer lifespan of robotic and CNC components

- Smooth, uninterrupted motion for 24/7 operations

Integration with Smart Sensors for Predictive Maintenance

With the rise of smart factories, the applications of plummer blocks now include integration with IoT-enabled sensors. These sensors monitor temperature, vibration, and lubrication levels in real time, helping predict maintenance needs before breakdowns occur. This proactive approach reduces downtime and improves overall equipment efficiency, aligning with modern predictive maintenance strategies. Leading plummer block manufacturer are now adopting smart design technologies to create durable, precision-engineered plummer blocks that support Industry 4.0 and enhance automation performance.

Advantages of smart integration:

- Real-time health monitoring of bearings

- Early detection of wear and misalignment

- Data-driven maintenance and cost savings

- Increased uptime and reduced machine failures

Conclusion

The applications of plummer blocks have proven to be an integral part of almost every industrial sector — from manufacturing and mining to agriculture, construction, and modern automation. These components silently power the world’s machinery by providing stability, reducing friction, and ensuring precise shaft alignment. Their strong design allows them to withstand high loads, harsh environments, and continuous operation — making them essential for industries that rely on efficiency and reliability.

In today’s age of smart manufacturing, the importance of plummer blocks goes beyond traditional mechanical support. With the rise of automation, robotics, and predictive maintenance systems, plummer blocks continue to evolve as smarter, more durable, and energy-efficient components. Choosing the right type and material of housing can significantly improve machine lifespan, minimize maintenance costs, and enhance overall operational output.

In short, the applications of plummer blocks represent the foundation of industrial progress — keeping machines running smoothly, production lines active, and operations efficient across every sector. Their adaptability and performance make them one of the most trusted components in modern engineering. Reputed SMSR gearbox manufacturer and industrial equipment suppliers often use plummer blocks alongside gear systems to ensure smooth power transmission, minimal vibration, and long-term reliability across various heavy-duty industrial applications.

FAQS

What are the main applications of plummer blocks?

The main applications of plummer blocks include supporting rotating shafts in machines across industries like manufacturing, mining, construction, and agriculture. They help maintain alignment, reduce friction, and enhance machine life by ensuring smooth and stable performance under heavy loads and continuous operation.

Why are plummer blocks used in industrial machinery?

Plummer blocks are used in industrial machinery to provide firm bearing support for rotating shafts. They reduce vibration, misalignment, and wear, improving machine efficiency and operational safety. Their durable design makes them suitable for heavy-duty and high-speed applications in multiple industries.

What are the uses of plummer block in the manufacturing industry?

In manufacturing, the uses of plummer block include supporting conveyors, rollers, and rotating machines. They ensure continuous production by maintaining alignment and minimizing friction. Their easy maintenance and long service life help factories achieve better performance with reduced downtime.

How do plummer blocks improve machine performance?

Plummer blocks improve machine performance by keeping shafts properly aligned and reducing friction between moving parts. This ensures smooth rotation, less energy consumption, and longer bearing life. As a result, machinery operates efficiently with lower maintenance costs and fewer breakdowns.

What types of plummer block housings are available?

Common types include cast iron, cast steel, and stainless-steel housings. The selection depends on working conditions—cast iron for general use, cast steel for heavy loads, and stainless steel for food, chemical, or outdoor applications that require corrosion resistance and long-term durability.

Are plummer blocks suitable for high-speed applications?

Yes, the applications of plummer blocks extend to high-speed machinery like CNC systems, conveyor belts, and automotive shafts. Their precision alignment, strong housings, and low-friction design make them ideal for maintaining smooth motion and stability even at high rotational speeds.

What is the difference between a plummer block and a pillow block?

Both support rotating shafts, but plummer blocks are heavier and used for industrial applications, while pillow blocks are lighter and for smaller, low-load machinery. Plummer blocks typically feature split housings for easy maintenance in heavy-duty operations.