What Are the Different Types of Conveyor Belt Systems?

In today’s fast-moving industrial world, conveyor belt systems play a vital role in ensuring smooth, efficient, and safe material handling. From manufacturing plants to logistics hubs and food processing industries, these systems make the movement of goods easier and faster.

However, not all conveyor systems are built the same — each industry requires a specific type designed to handle unique materials, speeds, and operating conditions. Understanding the different types of conveyor belt system is essential for improving productivity and reducing downtime.

Each conveyor belt system serves a unique purpose — from flat belt conveyors used in general manufacturing to modular and cleated belts designed for inclined transport or heavy loads. Choosing the right system can significantly enhance workflow efficiency, product quality, and workplace safety.As a trusted conveyor Gearbox manufacturer, we understand how the right conveyor setup, combined with efficient gearbox performance, can improve overall productivity and reduce maintenance downtime. In this blog, we’ll explore the most common types of conveyor belt systems, their features, and applications across various industries. Whether you’re an engineer, plant manager, or business owner, this guide will help you identify the ideal conveyor solution for your industrial requirements.

1. Flat Belt Conveyor System

A Flat Belt Conveyor System is one of the most common and versatile types of material-handling equipment used in various industries. It consists of a flat belt stretched over two or more pulleys, powered by a motor to move materials from one point to another efficiently. The belt is usually made from durable materials such as rubber, nylon, or PVC, depending on the application.

This system is primarily designed for transporting lightweight to medium-weight materials over short or moderate distances. The smooth, flat surface allows products to move without friction or vibration, making it ideal for assembly lines, inspection areas, and packaging processes.

The Flat Belt Conveyor System is known for its simple design, easy installation, and low maintenance cost, which makes it a preferred choice across industries like manufacturing, food processing, warehousing, and logistics.

Applications of Flat Belt Conveyor System

The Flat Belt Conveyor System is used in a wide range of industries where consistent and controlled material movement is required. In manufacturing units, it helps transfer products between workstations during assembly or production. In warehouses and logistics centers, it is used for sorting, packaging, and loading goods efficiently. The food and beverage industry uses it for handling packaged items and raw materials under hygienic conditions.

It is also widely used in airports for baggage handling, in e-commerce centers for product movement, and in the automotive sector for transporting parts on assembly lines. Because of its flexibility, a Flat Belt Conveyor System can be customized in length, width, and speed to match specific operational requirements across different industries.

Advantages of Flat Belt Conveyor System

The Flat Belt Conveyor System offers several advantages that make it one of the most trusted material-handling solutions. Its simple design ensures easy installation and maintenance, reducing downtime and operational costs. The system provides smooth and continuous transport, preventing product damage and ensuring gentle handling of materials.

It is also highly energy-efficient and can be easily integrated into automated systems, making it suitable for modern industrial operations. The flexibility to adjust the belt length, width, and speed allows businesses to use it for a variety of applications. Additionally, the Flat Belt Conveyor System is cost-effective, durable, and reliable — making it a long-term investment for industries seeking efficiency and productivity improvement.

When paired with the right types of conveyor pulley, its performance and lifespan can be further enhanced. Choosing suitable pulleys ensures smooth belt movement, reduced wear, and improved power transmission — creating a more efficient and reliable material-handling system overall.

2. Modular Belt Conveyor System

A Modular Belt Conveyor System is a modern type of conveyor designed with interlocking plastic modules that form a continuous and flexible belt surface.

These modular links are easy to assemble, disassemble, and clean, making the system highly efficient for industries where hygiene and flexibility are important. Unlike traditional flat belts, this design allows quick replacement of damaged sections without changing the entire belt.

The Modular Belt Conveyor System is widely used in industries such as food processing, packaging, pharmaceuticals, and logistics. It can easily handle curves, inclines, and declines, allowing for customized layouts in limited spaces. Its strong plastic construction resists corrosion, moisture, and wear, ensuring long service life and low maintenance costs.

Applications of Modular Belt Conveyor System

A Modular Belt Conveyor System is used in industries that require frequent cleaning or product movement through complex paths. In the food and beverage industry, it’s perfect for transporting bottles, containers, and packaged food items through washing, cooling, or packaging stages. In pharmaceutical and cosmetic plants, it ensures clean and contamination-free product handling.

The Modular Belt Conveyor System is also common in packaging, logistics, and manufacturing operations that require high-speed transport with curves or inclines. Because it’s easy to modify and expand, it’s ideal for facilities that change product lines or layouts frequently.

Advantages of Modular Belt Conveyor System

The Modular Belt Conveyor System offers several strong advantages over traditional belt conveyors. Its modular plastic design makes it durable and easy to maintain, as individual modules can be replaced instead of the entire belt. The open-surface structure allows quick cleaning and better airflow, making it ideal for industries with hygiene requirements.

It provides high flexibility, allowing smooth operation on curves and slopes while maintaining product stability. The system also supports custom configurations, operates quietly, and reduces maintenance downtime. Overall, a Modular Belt Conveyor System is a cost-effective, long-lasting, and reliable solution for modern industrial needs.

3. Cleated Belt Conveyor System

A Cleated Belt Conveyor System is a type of conveyor equipped with vertical cleats or barriers attached to the belt surface. These cleats prevent products from slipping or falling back during movement, especially when the belt operates at steep inclines or declines. It is specifically designed for transporting materials that need to stay in place while moving between different elevations.

The Cleated Belt Conveyor System is ideal for handling bulk materials like grains, powders, small parts, or packaged goods. It is often used in industries such as agriculture, mining, recycling, and food processing where products must be moved securely and efficiently.

Applications of Cleated Belt Conveyor System

A Cleated Belt Conveyor System is used in various industries that deal with bulk or granular materials. In agriculture, it helps move grains, seeds, and fertilizers at inclined angles. In mining and construction, it efficiently carries sand, gravel, and ores from one level to another.

In food processing, it’s used for moving items like chips, biscuits, or vegetables without product loss. The Cleated Belt Conveyor System also plays a vital role in packaging and sorting lines, where maintaining product spacing and orientation is essential for automated operations.

Advantages of Cleated Belt Conveyor System

The Cleated Belt Conveyor System provides excellent stability and grip, ensuring materials stay in place during inclined or declined movement. Its cleated design minimizes spillage and enhances transport efficiency, especially for loose or irregularly shaped products.

It offers customization flexibility, as cleats can be designed in various shapes, heights, and intervals to match specific materials or applications. The system is durable, easy to maintain, and suitable for continuous operation in demanding environments. Overall, the Cleated Belt Conveyor System improves productivity, reduces manual handling, and ensures reliable performance in industries dealing with uneven or vertical transport needs.

4. Incline and Decline Conveyor System

An Incline and Decline Conveyor System is designed to move materials between different height levels in a production or storage facility. It allows smooth and controlled transportation of goods either upward (incline) or downward (decline) without product slippage or loss. These conveyors use cleated, textured, or grip-style belts to securely hold products in place during elevation changes.

The Incline and Decline Conveyor System is ideal for industries that require multi-level movement of materials, such as packaging, warehousing, food processing, and logistics. It helps connect different machines, conveyors, or floors in an efficient and space-saving manner. With adjustable angles and customizable configurations, this system provides flexibility for different plant layouts and product types.

Applications of Incline and Decline Conveyor System

An Incline and Decline Conveyor System is widely used across industries to transport goods safely between various production stages. In warehouses and logistics centers, it helps move boxes or cartons between floors or mezzanine levels. In food and beverage plants, it transports packaged products from one processing level to another without damage.

In the agriculture and mining sectors, it is used to lift or lower bulk materials such as grains, sand, or stones efficiently. The Incline and Decline Conveyor System is also common in manufacturing and packaging units, where it connects machines positioned at different heights, ensuring smooth and continuous production flow.

Advantages of Incline and Decline Conveyor System

The Incline and Decline Conveyor System offers several key advantages for modern industries. Its main benefit is space optimization — allowing vertical movement of materials while minimizing floor space usage. It also reduces manual handling, improving workplace safety and efficiency.

With specially designed cleated or rough-surface belts, this system provides strong grip and product stability, even when moving at steep angles. It ensures smooth, reliable operation and can be integrated easily with automated sorting or packaging systems. Additionally, the Incline and Decline Conveyor System requires minimal maintenance and offers long-term performance, making it a cost-effective choice for continuous material handling operations.

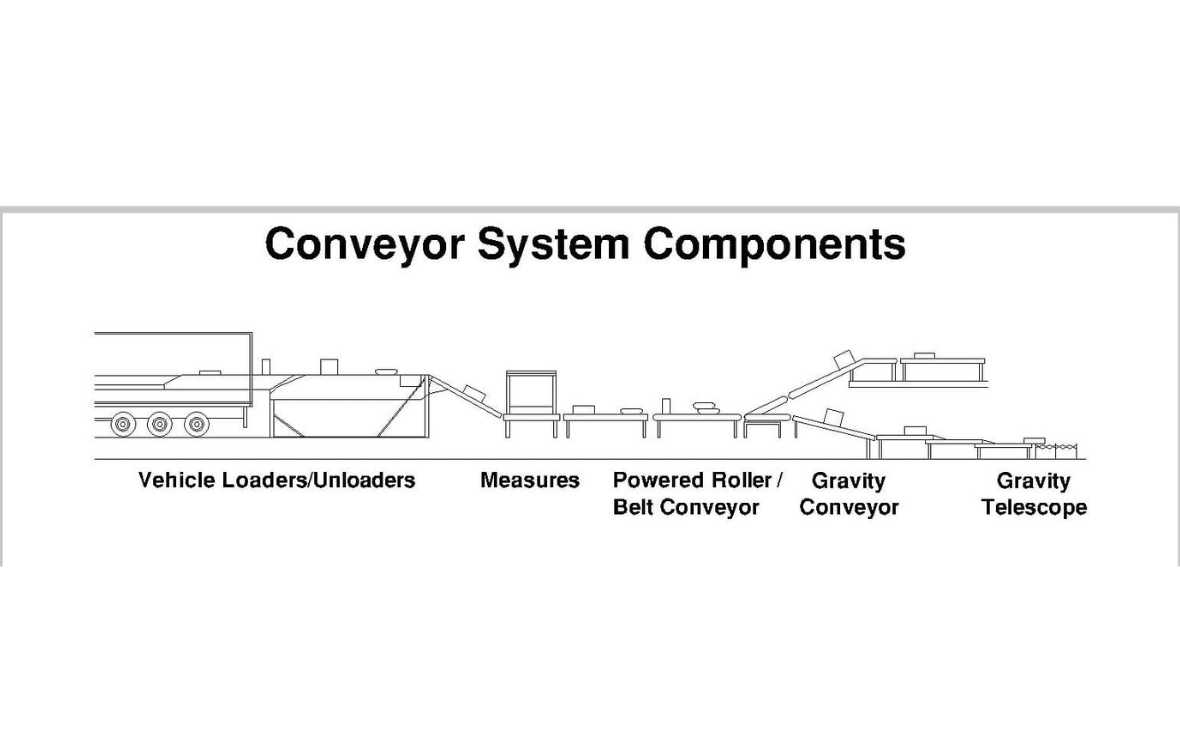

5. Roller Conveyor System

A Roller Conveyor System is a type of conveyor that uses a series of rollers mounted on a frame to move materials smoothly and efficiently. The rollers can be powered or non-powered (gravity-based), depending on the application. This system is mainly used for transporting heavy loads such as boxes, pallets, drums, and large containers in a straight or curved path.

The Roller Conveyor System is known for its strength, durability, and flexibility. It is widely used in industries like manufacturing, warehousing, automotive, packaging, and distribution centers. The system can be easily integrated with automated machinery and sensors, making it ideal for modern logistics and assembly operations.

Its simple design allows for easy maintenance and long service life, even under continuous heavy-duty usage.Different types of conveyor rollers — such as gravity rollers, powered rollers, and tapered rollers — can be used depending on the material weight and application.

Selecting the right roller type helps ensure smoother movement, reduced friction, and longer system lifespan, making the Roller Conveyor System more efficient and reliable for industrial operations.

Applications of Roller Conveyor System

The Roller Conveyor System is commonly used in industries where heavy or bulky materials need to be moved quickly and efficiently. In warehouses and logistics facilities, it helps transport packages, crates, and pallets between workstations or loading docks. In manufacturing units, it is used in assembly lines to move semi-finished or finished products through different stages of production.

In the automotive and packaging industries, a Roller Conveyor System is ideal for material transfer, inspection, and product accumulation before packaging. It is also used in airport baggage handling systems, postal centers, and e-commerce warehouses, where high-speed sorting and consistent product movement are essential for productivity.

Advantages of Roller Conveyor System

The Roller Conveyor System offers several benefits that make it one of the most reliable and cost-effective conveyor types. It provides excellent load-bearing capacity, making it suitable for handling heavy materials. The rollers ensure smooth and low-friction movement, which reduces wear and extends the lifespan of both the conveyor and transported goods.

This system is highly modular and customizable, allowing businesses to adjust the roller size, spacing, and drive mechanism according to their specific requirements. It can also be operated manually using gravity or with motorized rollers for automation. The Roller Conveyor System improves workflow efficiency, reduces manual labor, and supports continuous, safe, and precise material movement — making it a trusted choice for industries worldwide.

6. Magnetic Conveyor System

A Magnetic Conveyor System is a specialized type of conveyor that uses powerful magnets to move ferrous materials safely and efficiently along a production line. Instead of relying on friction or belts, it uses magnetic attraction to hold and transport metal items such as steel sheets, parts, or scrap materials. This makes it ideal for operations where stability, cleanliness, and precision are essential.

The Magnetic Conveyor System is commonly built with permanent magnets or electromagnets beneath a stainless-steel belt or slider bed. These magnets securely grip metal components during transport, even in vertical or inclined movements.

It is widely used in industries such as metalworking, automotive manufacturing, recycling, and stamping plants, where metal handling is a continuous process.

Applications of Magnetic Conveyor System

A Magnetic Conveyor System is extensively used in industries that handle metal parts or scrap. In metal fabrication and stamping plants, it transfers small steel parts, nails, screws, or metal chips from machines to storage or processing areas. In automotive manufacturing, it safely moves components like brackets and body parts without slippage or misalignment.

The Magnetic Conveyor System is also valuable in recycling facilities, where it separates ferrous materials from non-ferrous waste for efficient sorting. Additionally, it is used in machining centers and foundries to collect and transport metallic debris or coolant-contaminated chips, ensuring cleaner and safer production environments.

Advantages of Magnetic Conveyor System

The Magnetic Conveyor System provides numerous benefits, especially for industries dealing with ferrous materials. Its most significant advantage is secure and stable material handling, even at high speeds or steep inclines. Since magnets hold materials firmly in place, it minimizes product loss, contamination, and damage during transport.

This system also promotes clean and efficient operations, as there are no loose belts or moving parts that come into contact with the product. It requires minimal maintenance, offers high reliability, and can operate continuously in demanding industrial environments.

Furthermore, the Magnetic Conveyor System enhances workplace safety by reducing manual metal handling and supports automation in modern manufacturing setups.

7. Curved Conveyor System

A Curved Conveyor System is designed to transport materials smoothly around corners or obstacles without interrupting the flow of production. Unlike straight conveyors, it features a curved belt or roller section that allows products to change direction while maintaining alignment and speed. These systems are essential in plants or warehouses where space is limited and production lines require flexible layouts.

The Curved Conveyor System can be configured in various angles — typically 45°, 90°, or 180° — depending on the workflow design. It is available in both belt and roller types, depending on the weight and size of the material being handled. This system is commonly used in industries such as packaging, food processing, logistics, and e-commerce to create continuous, space-saving transport lines.

Applications of Curved Conveyor System

A Curved Conveyor System is widely used in warehouses, manufacturing units, and packaging plants where materials need to move efficiently between connected lines. In logistics and e-commerce fulfillment centers, it helps redirect cartons or parcels between sorting and dispatch areas.

In food and beverage production, curved conveyors are ideal for guiding packaged products around corners without tipping or damage. The Curved Conveyor System is also used in automotive and electronic assembly lines, where precise product movement and seamless transitions between machines are crucial.

Advantages of Curved Conveyor System

The Curved Conveyor System offers several advantages for modern manufacturing and logistics facilities. Its space-saving design allows efficient use of available floor area by eliminating the need for multiple straight conveyors. It provides smooth and continuous material flow, maintaining product orientation and speed even through sharp turns.

This system is highly customizable, allowing adjustments in angle, width, and radius to match specific plant layouts. It supports automation integration, enabling faster and safer operations in high-volume environments. Additionally, the Curved Conveyor System reduces manual handling, enhances production efficiency, and improves overall workflow flexibility — making it an essential part of modern industrial conveyor setups.

8. Timing Belt Conveyor System

A Timing Belt Conveyor System is a precision-driven conveyor designed for applications that require accurate positioning and synchronized movement of products. It uses toothed timing belts that engage perfectly with matching pulleys, ensuring consistent and slip-free transport. This unique design provides exceptional control over product spacing and speed, making it ideal for automated and high-precision industrial operations.

The Timing Belt Conveyor System is commonly used in industries such as automotive, electronics, packaging, and pharmaceuticals, where exact alignment and repeatable accuracy are critical. It offers a smooth and quiet operation, supports variable speeds, and can easily integrate with robotic systems and automated assembly lines.

Applications of Timing Belt Conveyor System

A Timing Belt Conveyor System is used in a wide range of precision-based applications. In automotive and electronics manufacturing, it transports parts and components through different assembly or testing stages with precise positioning. In packaging and labeling lines, it ensures accurate product spacing for sealing, cutting, or printing processes.

In pharmaceutical and medical industries, the Timing Belt Conveyor System is ideal for moving delicate bottles, blister packs, or containers without vibration or slippage. It is also used in robotic and automated production systems, where synchronization and exact timing are essential for smooth and efficient operations.

Advantages of Timing Belt Conveyor System

The Timing Belt Conveyor System offers several key advantages that make it indispensable for high-precision industries. Its toothed belt design ensures positive drive motion, eliminating slippage and maintaining accurate positioning. This results in improved productivity, precision, and reliability.

The system provides low noise operation, requires minimal maintenance, and supports high-speed performance. It can also be customized for multi-lane configurations, synchronized movement, or indexing applications. Additionally, the Timing Belt Conveyor System enhances automation efficiency, reduces downtime, and delivers long-term operational stability — making it one of the best solutions for precision-driven material handling.

9. Portable Conveyor System

A Portable Conveyor System is a lightweight, flexible, and movable material-handling solution designed for temporary or mobile operations. Unlike fixed conveyors, it can be easily transported, adjusted, and installed wherever needed. These systems are commonly used to move bulk materials, boxes, or products in locations where permanent conveyor setups are not practical.

The Portable Conveyor System typically comes with wheels or foldable frames for easy mobility and quick setup. It is powered by electric motors or gravity, depending on the application. Industries such as construction, agriculture, logistics, and warehousing use portable conveyors to handle short-term material movement efficiently. Their compact design and simple structure make them a cost-effective choice for on-site operations and flexible production environments.

Applications of Portable Conveyor System

A Portable Conveyor System is widely used in industries that require fast, temporary, or seasonal material handling. In construction and mining, it is used to transport sand, gravel, and stones from one area to another. In warehouses and distribution centers, it helps in loading and unloading trucks, improving workflow speed.

In agriculture, a Portable Conveyor System assists in moving grains, fertilizers, and other products efficiently between storage and processing units. It is also used in recycling facilities and packaging plants, where materials must be moved across short distances or between variable workstations.

Advantages of Portable Conveyor System

The Portable Conveyor System offers multiple advantages, especially for businesses that need mobility and flexibility. Its easy setup and portability make it ideal for changing job sites or temporary operations. It helps save time and labor, reducing the need for manual lifting and carrying heavy loads.

Because of its compact and adjustable design, it fits into small spaces and can be extended or shortened as required. The Portable Conveyor System is also cost-effective, energy-efficient, and simple to maintain, providing smooth and reliable performance in diverse environments. Whether for short-term projects or quick material transfer, this system ensures convenience, efficiency, and productivity in everyday operations.

What is Choosing the Right Conveyor Belt System?

Choosing the right Conveyor Belt System is one of the most important decisions for any industry involved in material handling or production. The correct system improves efficiency, reduces maintenance costs, and ensures safe and smooth movement of goods. Since every operation has unique requirements, selecting the right conveyor depends on factors such as material type, load capacity, speed, and working environment.

A well-selected Conveyor Belt System can transform workflow efficiency, minimize downtime, and enhance overall productivity. From flat and modular belts to roller and incline conveyors, each system serves a specific purpose. Understanding how these systems differ and which one best fits your industrial process helps achieve long-term performance and cost-effectiveness.

Factors to Consider When Selecting a Conveyor Belt System?

When selecting the right Conveyor Belt System, it’s essential to consider several key factors:

- Material Type: Choose a system based on whether the product is solid, fragile, wet, or bulky.

- Load Capacity: Ensure the conveyor can handle the weight and volume of materials consistently.

- Speed and Flow Rate: The system should maintain the desired throughput without product damage.

- Operating Environment: Consider temperature, humidity, dust, or hygiene requirements — especially in food and pharmaceutical industries.

- Maintenance and Durability: Opt for systems that offer easy cleaning, minimal downtime, and long-term reliability.

By analyzing these factors, businesses can select a Conveyor Belt System that enhances efficiency and aligns perfectly with their production goals.

Benefits of Selecting the Right Conveyor Belt System?

Choosing the right Conveyor Belt System provides several long-term advantages for industrial operations. It ensures consistent product flow, reduces manual handling, and boosts productivity. The right conveyor also minimizes breakdowns, saving both time and maintenance costs.

A properly selected system improves safety by preventing product spillage and workplace strain. It enhances energy efficiency, supports automation, and maintains product quality during movement. Overall, the right Conveyor Belt System becomes a valuable asset — improving workflow, reliability, and profitability in every industry.

Conclusion

In today’s fast-paced industrial world, conveyor belt systems have become the backbone of efficient and reliable material handling. From simple flat belts to advanced modular, cleated, and magnetic designs, every Conveyor Belt System serves a unique purpose in streamlining operations. Choosing the right system can make a significant difference in productivity, safety, and overall workflow performance.

Understanding the different types of conveyor belt systems helps industries select the most suitable solution for their specific needs — whether it’s for heavy-duty manufacturing, food processing, packaging, or logistics. Modern conveyor technologies now combine strength, flexibility, and automation, allowing companies to reduce manual labor, lower maintenance costs, and ensure consistent output quality.

A well-designed Conveyor Belt System not only enhances operational efficiency but also reflects a company’s commitment to innovation and safety. As industries continue to evolve, investing in the right conveyor system is not just a choice — it’s a long-term strategy for achieving sustainable growth and operational excellence.

Partnering with a trusted SMSR Gearbox manufacturer further ensures reliable power transmission, reduced maintenance costs, and improved system performance. The combination of a high-quality gearbox and an efficient conveyor design helps industries achieve smoother operations, extended equipment life, and consistent productivity across all stages of material handling.

FAQS

What is a Conveyor Belt System?

A Conveyor Belt System is a mechanical setup used to transport materials or products from one point to another efficiently. It consists of a belt driven by motors or rollers. These systems reduce manual labor, save time, and improve productivity in industries such as manufacturing, packaging, logistics, and food processing. Conveyor belt systems come in various types, each designed to handle specific materials, speeds, and industrial applications safely and smoothly.

What are the main types of Conveyor Belt Systems?

The most common types of Conveyor Belt Systems include flat belt, modular belt, cleated belt, roller, magnetic, curved, incline/decline, timing belt, portable, and food-grade conveyors. Each type serves a specific purpose — for example, flat belts for general transport, cleated belts for inclined movement, and modular belts for easy cleaning. The right conveyor system improves workflow efficiency, product safety, and material-handling speed in different industrial applications.

What is the use of a Flat Belt Conveyor System?

A Flat Belt Conveyor System is used for general material transport in manufacturing, packaging, and assembly lines. It moves lightweight to medium-weight products on a flat, smooth surface. Due to its simple design and easy maintenance, it’s one of the most widely used conveyors. Industries choose flat belt systems for consistent performance, flexibility, and cost-effectiveness in daily operations, making them a reliable choice for continuous production processes.

Where is a Modular Belt Conveyor System used?

A Modular Belt Conveyor System is commonly used in food processing, packaging, and pharmaceutical industries where frequent cleaning and flexibility are required. It uses interlocking plastic modules that can be easily replaced or reconfigured. This design allows the system to handle curved paths and inclined movements efficiently. It’s durable, corrosion-resistant, and ideal for operations that demand hygiene, quick maintenance, and long-term performance in challenging industrial environments.

What are the benefits of a Cleated Belt Conveyor System?

A Cleated Belt Conveyor System offers strong grip and stability during material movement on inclines or declines. The cleats prevent slippage, ensuring safe transport of bulk or irregularly shaped items like grains, powders, or packages. This system is used in industries such as agriculture, mining, and food processing. It’s highly customizable, durable, and efficient, making it perfect for conveying materials that require controlled spacing and secure handling.

Why is a Roller Conveyor System important in industries?

A Roller Conveyor System is essential for industries handling heavy loads such as boxes, pallets, or drums. It uses rollers to move materials smoothly with minimal friction. This system can operate manually using gravity or automatically through powered rollers. Commonly used in warehouses, automotive plants, and packaging units, roller conveyors improve workflow, reduce manual handling, and offer a cost-effective solution for high-volume material transfer.

What is a Magnetic Conveyor System used for?

A Magnetic Conveyor System is used for moving ferrous materials such as steel parts, screws, or scrap metal. It uses strong magnets beneath a belt to hold and transport metal objects securely, even in vertical or inclined directions. This system is popular in metalworking, recycling, and automotive industries. It ensures clean, safe, and efficient material movement, reduces manual handling, and supports automation in high-speed production environments.

How to choose the right Conveyor Belt System for your industry?

Choosing the right Conveyor Belt System depends on your product type, load capacity, operating speed, and environmental conditions. For example, flat belts are ideal for general transport, while cleated or incline conveyors are better for vertical movement. Consider factors like space, maintenance needs, and automation compatibility. Selecting the right system improves productivity, ensures safety, and delivers long-term operational efficiency tailored to your specific industrial requirements.