What Are Conveyor System Components? Complete Guide

In modern manufacturing and material handling environments, conveyor system components play a crucial role in ensuring smooth, efficient, and uninterrupted movement of materials. From small production units to large-scale industrial plants, conveyor systems are the backbone of operations where speed, accuracy, and reliability matter. However, the performance of a conveyor system depends not just on the belt or structure, but on the quality and coordination of each individual component working together.

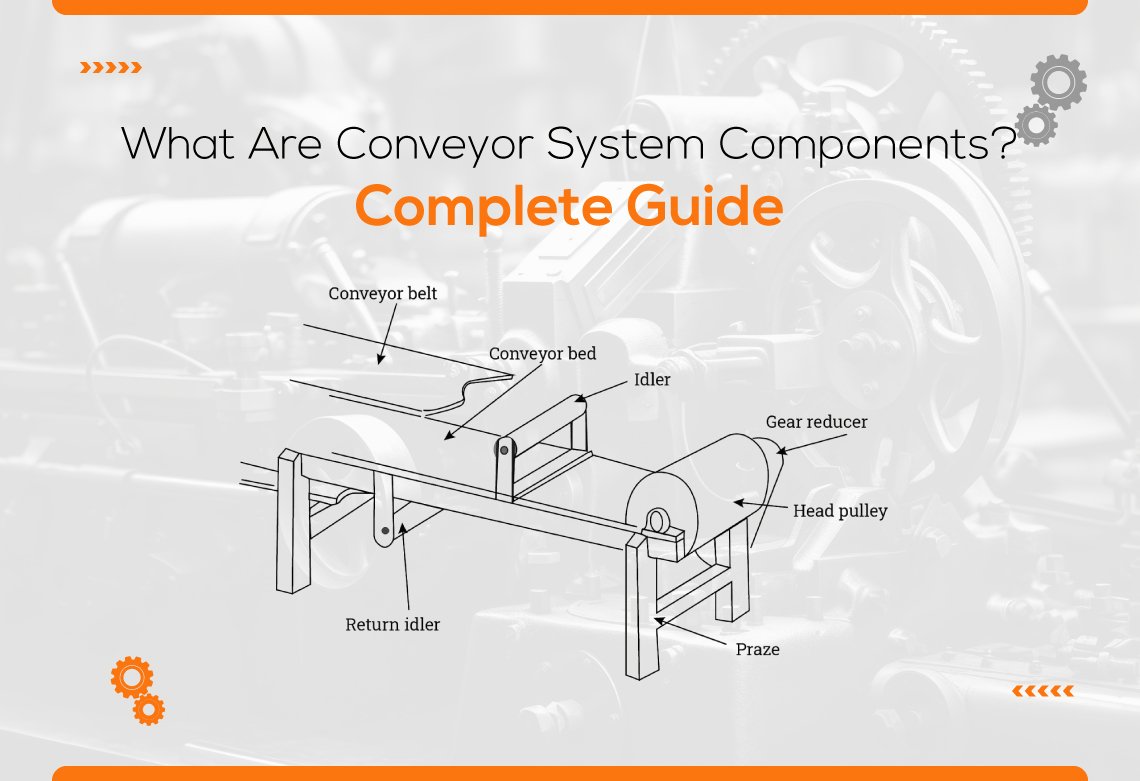

Conveyor system components include essential parts such as conveyor belts, rollers, idlers, gearboxes, drive units, pulleys, bearings, and support frames. Each component has a specific function—whether it is transmitting power, supporting loads, controlling speed, or maintaining alignment. When selected and maintained correctly, these components help industries reduce downtime, improve productivity, and ensure safe material flow across processes.

Understanding what conveyor system components are, how they function, and where they are used is important for plant managers, engineers, and procurement teams making equipment decisions. Different industries such as cement, mining, steel, power, and manufacturing rely on conveyor components designed for heavy loads, harsh environments, and continuous operation.

In this guide, we will explain the types of conveyor system components, their functions, and their industrial applications, helping you make informed choices for efficient and long-lasting conveyor performance.

What Are Conveyor System Components?

Conveyor System Components are the essential mechanical and structural parts that work together to move materials smoothly from one point to another within an industrial setup. These components form the backbone of any conveyor system and ensure controlled, continuous, and safe material flow.

Common conveyor system components include conveyor belts, rollers, idlers, gearboxes, motors, pulleys, bearings, frames, and tensioning devices. Each part has a specific role, such as supporting the load, transmitting power, maintaining belt alignment, or controlling speed.

In industrial environments like manufacturing plants, warehouses, cement units, and mining operations, conveyor system components are designed to handle different load capacities, speeds, and operating conditions. The overall performance of a conveyor system depends on how well these components are selected, installed, and maintained. High-quality conveyor system components improve efficiency, reduce breakdowns, and ensure long-term operational reliability.

Why Conveyor System Components Are Important in Material Handling

Conveyor System Components are critical in material handling because they directly impact productivity, safety, and operating costs. A well-designed conveyor system ensures smooth movement of materials with minimal manual effort and reduced risk of errors.

Key reasons why conveyor system components matter:

- They ensure consistent material flow without interruptions

- They reduce manual handling and labor costs

- They improve workplace safety and operational control

- They help prevent belt slippage and misalignment when supported by reliable solutions from a Conveyor Belt Tensioner Manufacturer

- They extend equipment life by minimizing wear and mechanical stress

When conveyor system components are properly engineered and maintained, industries can achieve higher efficiency, lower downtime, and more predictable production output, making them an essential part of modern material handling systems.

1. Main Components of a Conveyor System

The Conveyor System Components work together to move materials safely, smoothly, and efficiently across industrial operations.

Each component has a defined role, from carrying the load to transmitting power and maintaining alignment. When these components are selected correctly and maintained well, a conveyor system delivers consistent performance, reduced downtime, and long service life in demanding environments.

2. Conveyor Belt – Purpose, Types & Materials

The conveyor belt is the primary load-carrying element among Conveyor System Components. Its main purpose is to transport materials from one point to another with minimal spillage and controlled movement. Conveyor belts are selected based on load type, speed, and working conditions.

Common considerations include:

- Purpose-built belts for bulk, packaged, or abrasive materials

- Selection based on Types of Conveyor Belt Systems such as flat, troughed, or inclined setups

- Materials like rubber, PVC, fabric, steel cord, or heat-resistant compounds

A properly chosen belt improves efficiency and reduces wear on other conveyor system components.

3. Conveyor Rollers and Idlers

Conveyor rollers and idlers support the belt and the material being carried. They help reduce friction and guide the belt along its path. As critical Conveyor System Components, rollers ensure smooth rotation and proper belt tracking.

They are designed to:

- Support heavy loads without bending

- Maintain belt alignment

- Reduce energy consumption by minimizing resistance

High-quality rollers and idlers directly improve conveyor reliability and operating efficiency.

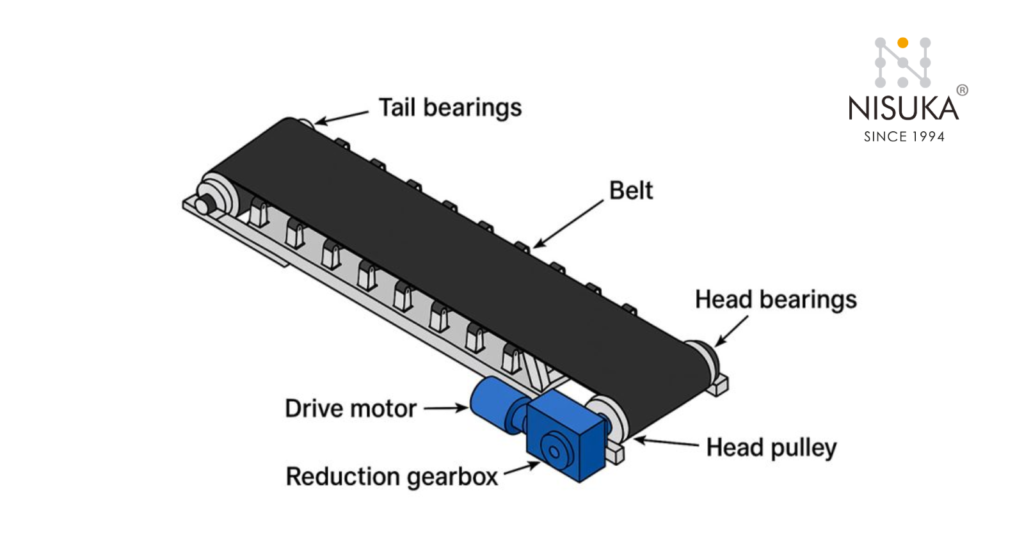

4. Conveyor Gearbox and Drive Unit

The gearbox and drive unit provide the power needed to move the conveyor belt. These Conveyor System Components control speed, torque, and direction of motion, making them vital for safe and efficient operation.

Their key functions include:

- Transmitting power from the motor to the conveyor

- Controlling speed based on load conditions

- Handling continuous or heavy-duty operations

A reliable drive system ensures smooth start-up and stable material flow.

5. Pulleys, Shafts and Bearings

Pulleys, shafts, and bearings are mechanical Conveyor System Components that support rotation and power transmission. Pulleys guide and tension the belt, shafts transfer rotational force, and bearings reduce friction.

Together, they:

- Maintain belt tension and alignment

- Support rotating parts under load

- Prevent excessive wear and vibration

Proper design and maintenance of these parts increase conveyor lifespan.

6. Conveyor Frame and Support Structure

The frame and support structure hold all Conveyor System Components in place. They provide strength, stability, and alignment to the entire system.

A well-designed structure:

- Supports static and dynamic loads

- Maintains correct component positioning

- Withstands industrial environments like dust, heat, and vibration

Strong support structures ensure safe operation and long-term conveyor performance.

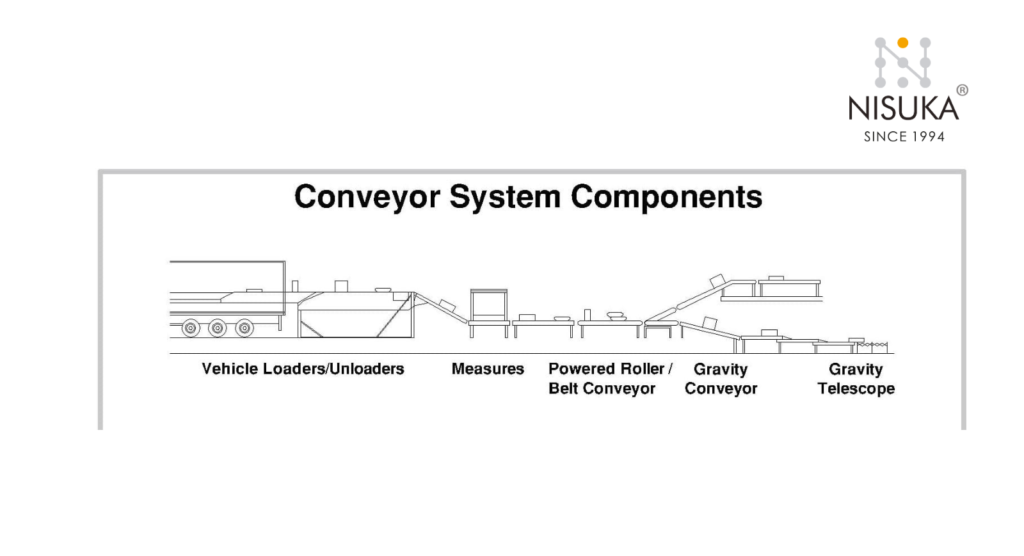

Types of Conveyor System Components

The Types of Conveyor System Components vary based on how and where a conveyor system is used. Different industries require different designs, load capacities, and material strengths. Selecting the right components according to application helps improve efficiency, safety, and equipment life.

Conveyor systems used in packaging units, manufacturing plants, or heavy industries all rely on application-specific components to deliver consistent performance.

1. Light-Duty Conveyor Components

Light-duty Types of Conveyor System Components are designed for low to moderate loads and smooth operating conditions. These components are commonly used in warehouses, assembly lines, food processing units, and packaging industries where material weight is limited.

They typically include:

- Lightweight conveyor belts made from PVC or fabric

- Small-diameter rollers and idlers

- Compact drive units with lower power ratings

- Simple support frames for short conveyor lengths

Light-duty components help achieve efficient material movement with lower energy consumption and minimal maintenance.

2. Heavy-Duty Conveyor Components

Heavy-duty Types of Conveyor System Components are built to handle high loads, continuous operation, and tough working conditions. These components are widely used in cement plants, mining operations, steel industries, and power plants.

Key characteristics include:

- High-strength conveyor belts for bulk material handling

- Large rollers and reinforced idlers

- Powerful gearboxes and drive systems

- Heavy conveyor drum pulleys sourced from trusted Conveyor Drum Pulley manufacturer

- Strong steel frames and support structures

These components ensure reliable performance under heavy stress and reduce the risk of breakdowns.

Industrial Applications of Conveyor System Components

The Applications of Conveyor System Components are widespread across industries where continuous, safe, and efficient material movement is required. These components help industries reduce manual handling, improve productivity, and maintain smooth workflow across operations.

Depending on the industry, conveyor system components are designed to handle bulk materials, heavy loads, or fast-moving packaged goods. Proper selection ensures reliability, lower downtime, and long-term operational efficiency

1. Cement, Mining and Quarry Industries

In cement plants, mining sites, and quarries, the Applications of Conveyor System Components focus on handling heavy, abrasive, and high-volume materials. Conveyor systems are used to transport raw materials like limestone, coal, clinker, and aggregates over long distances.

These industries rely on:

- Heavy-duty conveyor belts for bulk material movement

- Strong rollers, idlers, and pulleys to support high loads

- Reliable drive systems supplied by an experienced conveyor gearbox manufacturer

- Components designed to withstand dust, impact, and continuous operation

Well-designed conveyor components help minimize breakdowns and ensure uninterrupted production in harsh environments.

2. Steel, Power and Heavy Manufacturing Plants

The Applications of Conveyor System Components in steel, power, and heavy manufacturing plants involve moving hot materials, metal parts, ash, and finished goods. Conveyor systems play a critical role in maintaining production flow and workplace safety.

Key uses include:

- Transporting raw materials and finished products

- Handling heavy and high-temperature materials

- Supporting automated production lines

Durable conveyor system components ensure stable operation, high load capacity, and consistent performance in demanding industrial conditions.

3. Warehousing and Logistics Operations

In warehouses and logistics centers, the Applications of Conveyor System Components are focused on speed, accuracy, and efficiency. Conveyor systems help move packages, cartons, and goods quickly across sorting, packing, and dispatch areas.

These operations depend on:

- Light to medium-duty conveyor components

- Smooth rollers and belts for fast material flow

- Compact and energy-efficient drive systems

By using the right conveyor system components, logistics operations can improve order accuracy, reduce labor effort, and handle high volumes efficiently.

Common Problems in Conveyor System Components

Common Problems in Conveyor System Components can reduce productivity, increase downtime, and raise maintenance costs if they are not identified early. Conveyor systems operate continuously under load, which makes their components vulnerable to mechanical stress, environmental factors, and improper usage.

Issues such as wear, misalignment, and drive failures are among the most frequent problems faced by industries using conveyor systems. Understanding these problems helps plant operators take preventive action and maintain smooth material flow.

1. Wear and Tear of Conveyor Parts

Wear and tear is one of the most frequent Common Problems in Conveyor System Components, especially in systems handling heavy or abrasive materials. Continuous movement, load impact, and friction gradually reduce the strength of belts, rollers, pulleys, and bearings.

Common causes include:

- Handling abrasive or sharp materials

- Continuous operation without proper maintenance

- Poor-quality or mismatched components

Regular inspection and timely replacement of worn parts can prevent sudden breakdowns and extend equipment life.

2. Misalignment and Vibration Issues

Misalignment and vibration are serious Common Problems in Conveyor System Components that can damage multiple parts at the same time. When belts, rollers, or pulleys are not aligned properly, they create uneven stress and excessive vibration.

These issues often lead to:

- Belt tracking problems and spillage

- Increased noise during operation

- Faster wear of bearings and rollers

Proper installation, regular alignment checks, and balancing of rotating parts help control vibration and ensure stable conveyor performance.

3. Gearbox and Roller Failures

Gearbox and roller failures are critical Common Problems in Conveyor System Components because they directly affect conveyor movement. Gearbox issues may occur due to overloading, poor lubrication, or incorrect selection for the application.

Common reasons include:

- Excessive load beyond design limits

- Inadequate lubrication or maintenance

- Use of unsuitable gearboxes for heavy applications

Industries handling extreme loads often rely on expertise from Stone Crusher Gearbox Manufacturer to ensure the gearbox can withstand harsh working conditions. Using the right gearbox and maintaining rollers properly helps prevent unexpected stoppages and costly repairs

Conclusion

Understanding conveyor system components is essential for achieving smooth, safe, and efficient material handling in any industrial setup. From belts and rollers to gearboxes and support structures, each component plays a critical role in maintaining performance and minimizing downtime. When these components are selected based on application, load conditions, and working environment, industries can improve productivity, reduce maintenance costs, and extend equipment life.

Regular inspection, proper alignment, and timely maintenance help prevent common problems such as wear, vibration, and mechanical failure. Using high-quality components from reliable suppliers, including an experienced SMSR Gearbox manufacturer, ensures stable power transmission and consistent conveyor operation even in demanding conditions.

Overall, investing in the right conveyor system components and maintaining them correctly leads to better operational efficiency, improved safety, and long-term cost savings for industries across cement, mining, manufacturing, and logistics sectors.

FAQS

What are the main components of a conveyor system?

The main components of a conveyor system include the conveyor belt, rollers, idlers, gearbox, motor, pulleys, bearings, shafts, and support frame. All these conveyor system components work together to move materials smoothly, safely, and efficiently across industrial operations.

Why are conveyor system components important in industries?

Conveyor system components are important because they ensure continuous material flow, reduce manual handling, improve safety, and increase productivity. Properly designed components help industries minimize downtime, control operating costs, and maintain consistent performance in manufacturing, mining, and logistics environments.

What types of conveyor system components are used in heavy industries?

Heavy industries use reinforced conveyor belts, heavy-duty rollers, strong pulleys, robust gearboxes, and steel support structures. These conveyor system components are designed to handle high loads, abrasive materials, and continuous operation in cement plants, mining sites, and steel manufacturing units.

How do conveyor system components affect conveyor efficiency?

Conveyor system components directly impact efficiency by controlling speed, alignment, load support, and power transmission. High-quality components reduce friction, prevent material spillage, and ensure smooth operation, resulting in lower energy consumption, fewer breakdowns, and improved overall conveyor system performance.

What causes failure in conveyor system components?

Failures in conveyor system components are usually caused by overloading, poor maintenance, misalignment, improper lubrication, and use of low-quality parts. Environmental factors like dust, heat, and moisture also contribute to faster wear and mechanical breakdowns if not managed properly.

How often should conveyor system components be maintained?

Conveyor system components should be inspected regularly, with basic checks done weekly and detailed maintenance scheduled monthly or quarterly. Proper maintenance helps detect wear, alignment issues, and lubrication problems early, preventing sudden failures and extending the life of the conveyor system.

Which conveyor system components require frequent replacement?

Components like conveyor belts, rollers, idlers, bearings, and seals usually require more frequent replacement due to continuous movement and load stress. Regular monitoring of these conveyor system components helps avoid unexpected downtime and maintains smooth material handling operations.