What is a Conveyor Magnet? Complete Guide

In modern industrial operations, maintaining product purity and protecting equipment from metal contamination are critical for achieving efficiency and reducing operational risks. This is where conveyor magnets play an essential role.

A conveyor magnet is a specialized magnetic separation device designed to remove ferrous metal particles from materials moving along conveyor belts. Widely used across industries such as mining, recycling, cement, food processing, and manufacturing, conveyor magnets help prevent equipment damage, minimize downtime, and ensure consistent product quality.

As industrial processes become more automated and production speeds increase, the need for reliable and efficient metal separation solutions has grown significantly. Conveyor magnets provide a cost-effective and continuous method of eliminating unwanted metal contaminants without interrupting workflow.

By integrating advanced magnetic technology into conveyor systems, businesses can improve safety, extend machinery lifespan, and enhance overall operational performance. Similarly, working with a trusted SMSR Gearbox manufacturer ensures reliable power transmission and smooth conveyor operations, helping industries maintain efficiency and long-term productivity.

This complete guide explores everything you need to know about conveyor magnets, including their definition, working principles, types, key benefits, and industrial applications.

Whether you are a plant manager, engineer, or business owner looking to understand magnetic separation solutions, this article will provide clear, practical insights to help you make informed decisions based on industry best practices and expert knowledge.

What is a Conveyor Magnet?

A conveyor magnet is a specialized magnetic device installed above, below, or along a conveyor belt to automatically remove ferrous metal contaminants from moving materials. When industries ask What is a Conveyor Magnet?, the simple answer is that it is a magnetic separation system designed to protect equipment, improve product quality, and ensure smooth production processes.

These magnets use strong magnetic fields to attract and capture iron or steel particles while allowing non-magnetic materials to continue moving along the conveyor. Because of this automatic separation, conveyor magnets are widely used in industries where metal contamination can cause damage, safety risks, or product defects.

Understanding What is a Conveyor Magnet? is important for industries such as mining, recycling, cement, food processing, and manufacturing. These systems help prevent costly breakdowns by removing unwanted metal pieces before they reach crushers, grinders, or sensitive machinery. Conveyor magnets are available in different designs, including suspension magnets, overband magnetic separators, permanent magnets, and electromagnetic systems, allowing businesses to choose the right solution based on material type and operational needs.

Key functions and advantages include:

- Continuous removal of tramp iron without stopping production

- Protection of conveyor equipment and downstream machines

- Improved product purity and compliance with industry standards

- Reduced maintenance costs and operational downtime

- Increased efficiency through automated separation

In simple terms, What is a Conveyor Magnet? It is an essential industrial tool that combines magnetic technology with conveyor systems to create safer, cleaner, and more efficient material handling operations.

By integrating conveyor magnets into production lines, companies can achieve reliable metal separation while maintaining consistent workflow and operational productivity. Similarly, working with a reliable Plummer Block Manufacturer helps ensure proper shaft support and smooth mechanical performance within conveyor systems, improving overall operational reliability.

How Does a Conveyor Magnet Work?

Understanding How Does a Conveyor Magnet Work is important for industries that want to improve material handling efficiency and protect equipment from metal contamination.

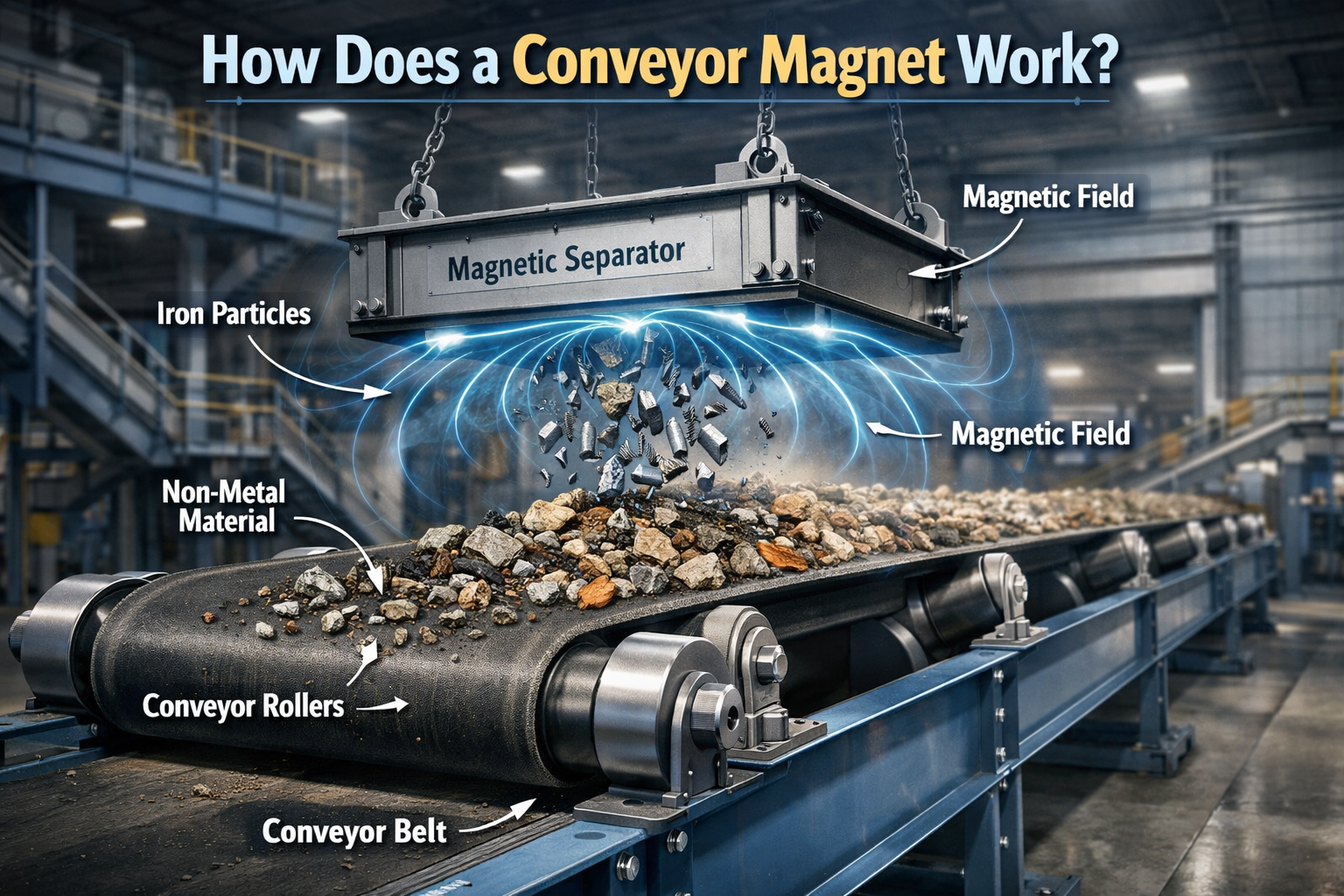

A conveyor magnet works by creating a strong magnetic field that attracts and removes ferrous metals such as iron and steel from materials moving on a conveyor belt. This process happens automatically while production continues, making it a reliable and efficient solution for continuous operations.

The basic principle behind How Does a Conveyor Magnet Work is magnetic separation. As bulk material travels along the conveyor, the magnet is positioned either above, below, or across the belt. When ferrous particles pass through the magnetic field, they are pulled away from the main material flow and held against the magnet or discharged separately depending on the system design. Non-magnetic materials continue moving forward without interruption.

Key steps involved in the working process include:

- Material moves along the conveyor belt during normal operation

- The magnetic field targets only ferrous metal contaminants

- Metal particles are lifted or attracted toward the magnet

- Clean material continues along the conveyor path

- Captured metal is either manually removed or automatically discharged

Different types of conveyor magnets may work slightly differently. Permanent magnets use fixed magnetic strength without electricity, while electromagnetic systems allow adjustable magnetic power for heavy-duty applications.

Self-cleaning overband magnets use rotating belts to automatically remove collected metal, reducing manual maintenance. Many users also ask What is a suspended magnet?, which refers to an overhead magnetic system designed to capture and remove ferrous contaminants from conveyor belts efficiently.

Knowing How Does a Conveyor Magnet Work helps engineers and operators choose the right system for their needs. Proper installation and alignment ensure maximum efficiency and better separation results. Overall, conveyor magnets provide a simple yet powerful method for protecting machinery, improving product quality, and maintaining smooth industrial processes through reliable magnetic separation technology.

Types of Conveyor Magnets

Understanding the Types of Conveyor Magnets helps industries select the right magnetic separation system based on material handling needs, contamination level, and production environment. Conveyor magnets are designed to remove ferrous metals from conveyor belts automatically, improving equipment protection and product quality.

Different industries require different magnet designs, which is why knowing the main Types of Conveyor Magnets is important for efficient and safe operations.

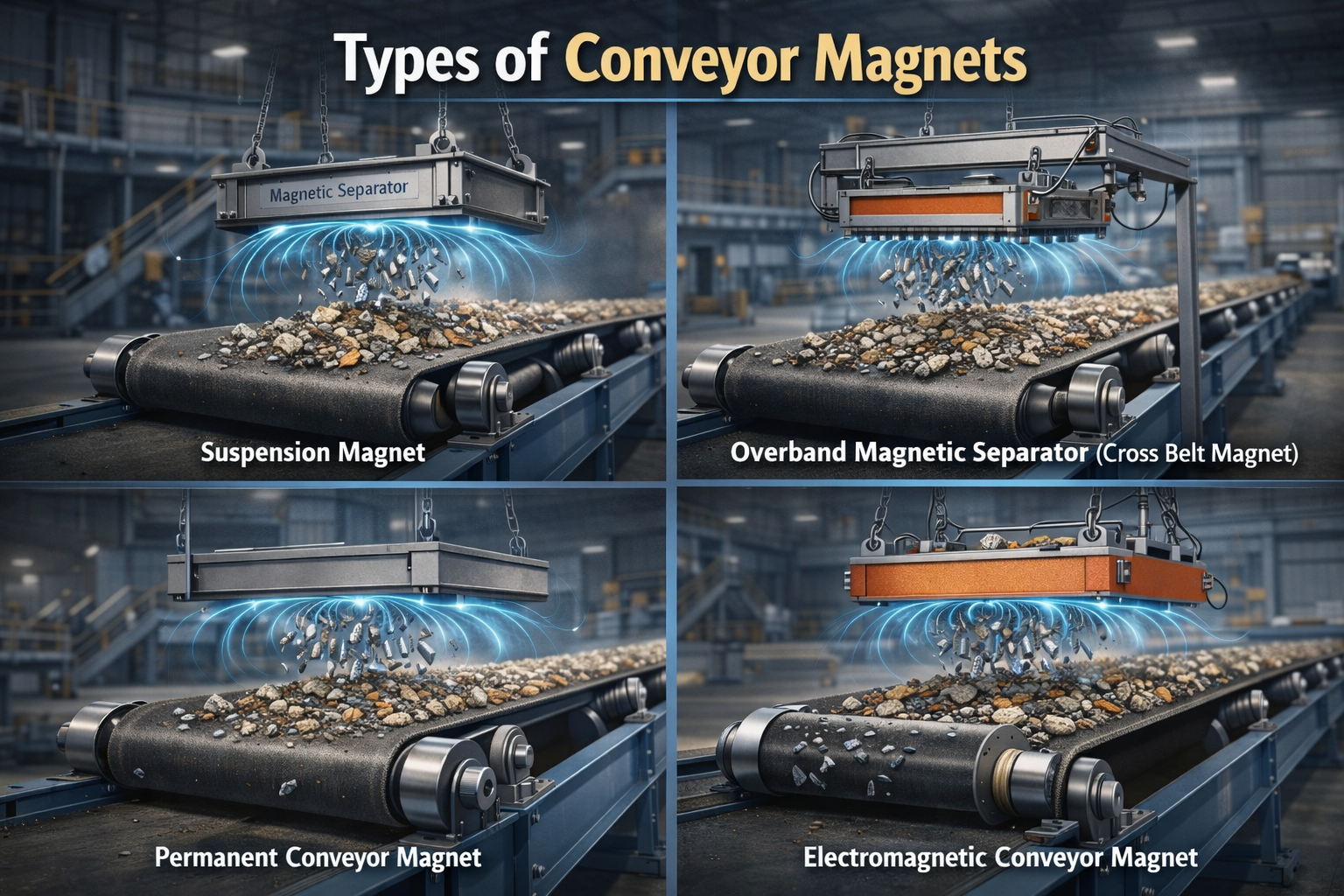

1. Suspension Magnet

Suspension magnets are installed above conveyor belts to capture tramp iron from moving materials. These magnets are commonly used in mining, cement, and recycling industries. They are easy to install and provide continuous protection by attracting metal contaminants before they reach sensitive equipment.

Choosing a reliable Suspension magnet manufacturer ensures high magnetic strength, durable design, and consistent performance for long-term industrial use.

2. Overband Magnetic Separator (Cross Belt Magnet)

Overband magnets are one of the most popular Types of Conveyor Magnets for heavy-duty applications. They are mounted across the conveyor belt and often include a self-cleaning system that automatically removes collected metal. This reduces manual labor and ensures uninterrupted production.

3. Permanent Conveyor Magnet

Permanent conveyor magnets use strong magnetic materials such as ferrite or rare-earth magnets. They do not require electricity, making them energy-efficient and low maintenance. These systems are suitable for operations where consistent magnetic strength is sufficient.

4. Electromagnetic Conveyor Magnet

Electromagnetic conveyor magnets use electric power to generate magnetic force. The main advantage is adjustable magnetic strength, which makes them ideal for handling heavy or deep-buried metal contaminants in demanding industrial environments.

Key benefits of choosing the right Types of Conveyor Magnets include:

- Improved material purity

- Reduced equipment damage

- Increased operational efficiency

- Lower maintenance costs

Selecting the appropriate conveyor magnet type ensures reliable separation performance and long-term operational success.

Key Benefits of Using Conveyor Magnets

Understanding the Key Benefits of Using Conveyor Magnets helps industries improve operational efficiency, reduce risks, and maintain high-quality production standards. Conveyor magnets are widely used in material handling systems to automatically remove ferrous metal contaminants from bulk materials moving on conveyor belts. These systems support continuous operations without manual interruption, making them an essential component in modern industrial processes.

By integrating magnetic separation technology, businesses can enhance safety, protect valuable equipment, and ensure smooth workflow, similar to following a proper Gearbox Selection Guide for Your Application to optimize mechanical performance and reliability

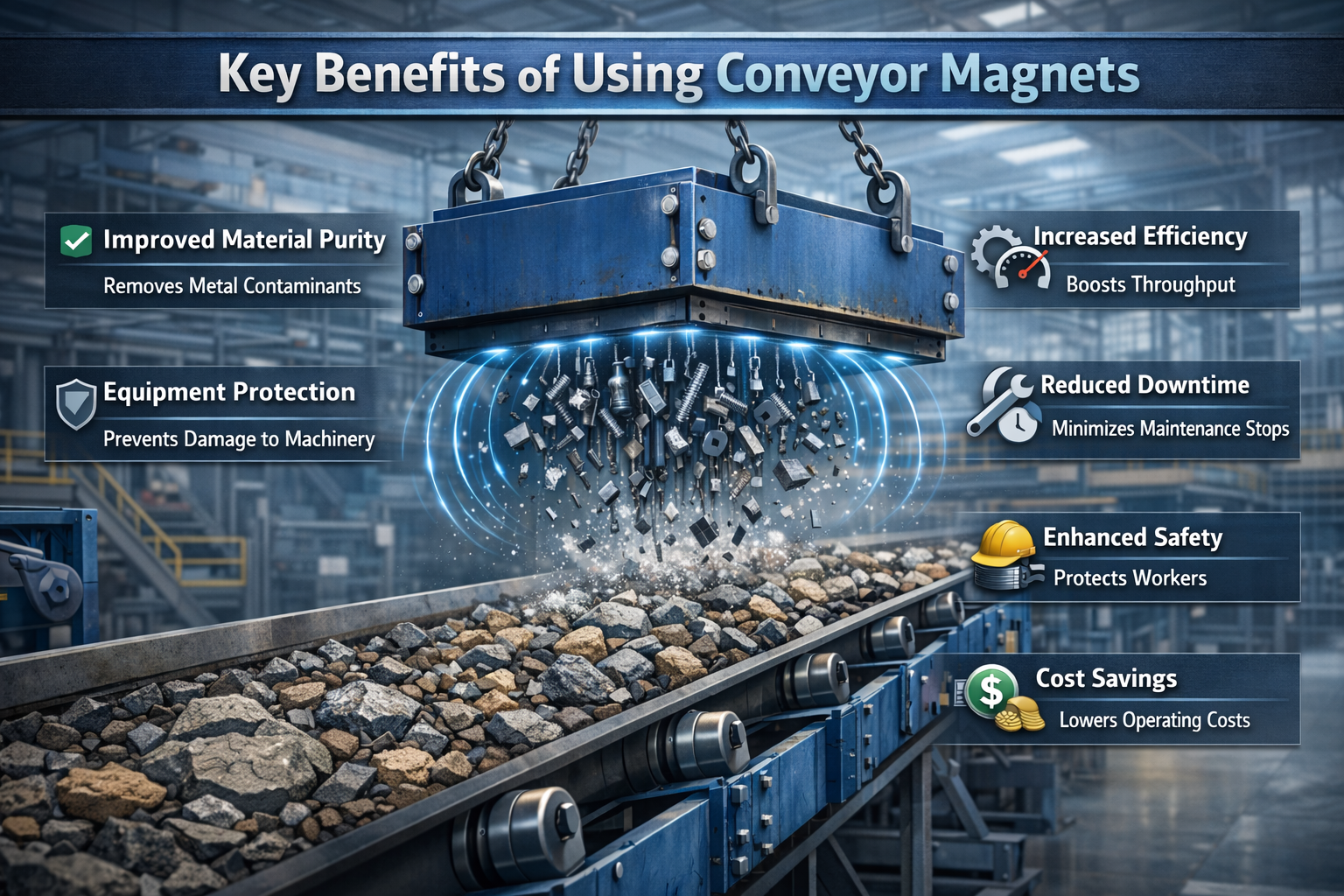

1. Equipment Protection

One of the major Key Benefits of Using Conveyor Magnets is protecting machinery from damage caused by tramp iron or unwanted metal particles. Removing metal before it reaches crushers, grinders, or processing machines helps prevent costly repairs and production delays.

2. Improved Product Quality

Conveyor magnets help maintain clean and contamination-free materials. Industries such as food processing, recycling, and manufacturing rely on magnetic separation to meet quality standards and improve customer satisfaction.

3. Reduced Downtime and Maintenance

Automatic metal removal reduces the need for frequent machine shutdowns. This leads to lower maintenance costs and improved operational reliability, which is a key advantage for high-volume production environments.

4. Increased Operational Efficiency

Another important aspect of the Key Benefits of Using Conveyor Magnets is continuous separation during production. Automated systems save time and reduce labor requirements, allowing processes to run smoothly and efficiently.

5. Enhanced Workplace Safety

By removing hazardous metal pieces from conveyor systems, conveyor magnets reduce safety risks for workers and help maintain a safer working environment.

Overall, understanding the Key Benefits of Using Conveyor Magnets allows industries to optimize performance, increase productivity, and maintain long-term operational success through reliable magnetic separation solutions.

Industrial Applications of Conveyor Magnets

Understanding the Industrial Applications of Conveyor Magnets helps industries improve efficiency, maintain product quality, and protect expensive machinery from metal contamination. Conveyor magnets are widely used in different sectors where bulk materials are transported through conveyor systems. Below are key industries where conveyor magnets play a critical role.

1. Mining and Quarry Industry

In mining and quarry operations, conveyor belts carry heavy materials such as coal, minerals, and aggregates that may contain tramp iron or metal debris. Conveyor magnets automatically remove these metal contaminants, preventing damage to crushers, screens, and processing equipment. This improves equipment lifespan, reduces unexpected breakdowns, and ensures smoother operations.

Mining companies rely on magnetic separation to maintain consistent productivity while reducing maintenance costs and improving safety in high-volume material handling environments.

2. Recycling and Waste Management

Recycling facilities use conveyor magnets to separate ferrous metals from mixed waste streams efficiently. Magnetic separation improves sorting accuracy and helps recover valuable metal resources for reuse. By removing iron and steel automatically, conveyor magnets increase recycling efficiency and reduce manual labor. They also help maintain cleaner processing lines, ensuring higher-quality recycled materials.

This application supports sustainable practices by improving waste management processes and contributing to environmentally responsible industrial operations.

3. Cement and Construction Industry

In cement plants and construction material processing, conveyor magnets help remove metal contaminants from raw materials such as limestone, sand, or clinker. Removing metal protects grinding mills and kilns from damage caused by unwanted iron pieces.

Conveyor magnets enhance operational reliability by preventing equipment wear and reducing downtime. Their use ensures consistent production quality and helps maintain efficient material flow, making them an important component in cement manufacturing and construction material handling systems.

4. Food Processing and Packaging

Food processing industries require strict quality control to ensure safety and compliance with regulations. Conveyor magnets are used to remove metal particles from food ingredients during processing or packaging stages. This helps prevent contamination, protects processing equipment, and ensures product safety.

Magnetic separation improves consumer trust by maintaining high hygiene standards and supporting regulatory compliance. Conveyor magnets are commonly used in grain processing, sugar production, and packaged food manufacturing environments.

5. Power Plants and Bulk Material Handling

Power plants handling coal or biomass use conveyor magnets to remove metal debris before materials enter crushers or boilers. This protects equipment from damage and ensures uninterrupted power generation. Conveyor magnets improve fuel quality by eliminating unwanted metal contaminants that may affect performance.

Their application helps reduce maintenance costs, improve operational efficiency, and maintain consistent material flow within bulk handling systems commonly used in energy production facilities.

Final Thoughts

Understanding what a conveyor magnet is and how it works is essential for industries that rely on efficient and safe material handling systems. Conveyor magnets are more than just separation tools; they are a critical part of modern industrial operations designed to protect machinery, improve product quality, and maintain consistent workflow.

By automatically removing ferrous metal contaminants from conveyor belts, these systems help reduce equipment damage, minimize downtime, and enhance operational efficiency.

Throughout this guide, we explored the working principles, different types, key benefits, and industrial applications of conveyor magnets. Each aspect highlights how magnetic separation technology contributes to safer and more productive industrial environments.

Whether used in mining, recycling, food processing, cement manufacturing, or power generation, conveyor magnets provide reliable performance and long-term value.

Choosing the right conveyor magnet depends on factors such as material type, conveyor speed, and operational requirements. Businesses should evaluate their needs carefully and work with experienced manufacturers or suppliers to ensure optimal results. With increasing automation and higher production demands, investing in effective magnetic separation solutions has become more important than ever. Many buyers also research the top 10 suspension magent manufacturer in Tamil nadu to compare quality, expertise, and industry reputation before making a purchase decision.

In conclusion, conveyor magnets are essential for maintaining equipment safety, improving efficiency, and ensuring high-quality output, making them a valuable addition to any industrial conveyor system focused on reliability and performance.

FAQS

Are conveyor magnets safe for industrial environments?

Conveyor magnets are designed with safety in mind. Proper installation and maintenance reduce risks caused by loose metal debris. However, operators should follow safety guidelines and maintain proper distance from strong magnetic fields during operation.

How often should conveyor magnets be maintained?

Regular inspection and cleaning are recommended depending on usage and contamination level. Maintenance typically includes checking magnet positioning, cleaning accumulated metal, and inspecting mounting structures to ensure optimal performance and long-term reliability.

Can conveyor magnets improve operational efficiency?

Yes, conveyor magnets increase efficiency by automatically removing metal contamination, reducing equipment damage, and minimizing unexpected downtime. This helps maintain consistent production flow and lowers maintenance costs, making them a valuable investment for industrial facilities.

Can conveyor magnets be customized for specific industries?

Yes, conveyor magnets can be customized based on conveyor size, material type, and industrial requirements. Manufacturers often provide tailored solutions to achieve maximum separation efficiency and meet specific operational needs.

What is the difference between self-cleaning and manual conveyor magnets?

Self-cleaning conveyor magnets automatically discharge captured metal using a moving belt or mechanism, reducing manual work. Manual-cleaning magnets require operators to periodically remove collected metal. Self-cleaning systems are preferred for high-volume industrial applications because they maintain continuous operation.