Types of Conveyor Rollers and Their Uses

Conveyor systems are the backbone of modern industries, helping businesses move products, raw materials, and heavy loads with speed and efficiency. At the heart of these systems are conveyor rollers, which play a vital role in ensuring smooth, reliable, and cost-effective material handling.

Whether it’s a warehouse, manufacturing unit, mining site, or food processing plant, conveyor rollers are essential for reducing manual labor and streamlining operations.

A conveyor roller may look like a simple cylindrical component, but its type, material, and design determine how well it performs in specific environments. From gravity rollers used in packaging lines to impact rollers that handle heavy-duty loads in mining, each type has a unique purpose. Choosing the right conveyor roller not only increases productivity but also minimizes downtime, energy consumption, and equipment wear and tear.

In this blog, we will explore the different types of conveyor rollers and their uses, including gravity, motorized, impact, guide, tapered, and specialized rollers.

You’ll also discover how industries like manufacturing, logistics, and pharmaceuticals benefit from them, and which factors to consider when selecting the right roller for your system. Understanding these details will help businesses improve efficiency, cut costs, and ensure long-term reliability.

What Are Conveyor Rollers?

Many people often search what are Conveyor Rollers when trying to understand their role in modern industries. Conveyor rollers are cylindrical components that form the foundation of conveyor systems, enabling smooth and efficient movement of goods, raw materials, and heavy loads.

They are typically mounted inside conveyor frames and allow products to move with minimal friction, either manually, by gravity, or through powered systems.

The design of conveyor rollers may seem simple, but they are essential in reducing manual effort and ensuring continuous workflow. Depending on their material and type, rollers can transport everything from lightweight packages in warehouses to heavy-duty ores in mining plants. Their use helps industries save time, lower labor costs, and improve workplace safety.

When learning what are Conveyor Rollers, it’s important to note that they come in many types, such as gravity rollers, motorized rollers, impact rollers, and stainless-steel rollers. Each serves a different purpose based on industry requirements. From logistics and manufacturing to pharmaceuticals and food processing, conveyor rollers keep operations running smoothly.

In short, they are the backbone of material handling systems, ensuring efficiency, productivity, and long-term reliability across industries. Similarly, industries often rely on trusted SMSR Gearbox manufacturer solutions to complement conveyor systems, ensuring powerful performance and durability in heavy-duty applications.

Why Conveyor Rollers Are Important?

Understanding what are Conveyor Rollers also means knowing why they are so important. Conveyor rollers reduce human labor by automating the movement of goods.

They enable companies to handle large volumes of materials quickly and with minimal effort.This efficiency leads to reduced operational costs, faster output, and higher safety in workplaces.

Conveyor rollers also minimize product damage, as goods are transported smoothly without unnecessary handling. For industries like food processing and pharmaceuticals, this ensures quality and compliance with safety standards. In heavy industries, rollers protect equipment by distributing loads evenly and preventing system breakdowns.

In simple terms, conveyor rollers are important because they improve speed, consistency, and reliability in material handling. Just as structured training improves performance in a classroom, rollers streamline production lines in industries. Without them, processes would be slower, more costly, and prone to errors.

Their significance lies not only in moving products but also in enhancing productivity and long-term industrial growth.

Industries That Commonly Use Conveyor Rollers

When exploring what are Conveyor Rollers, it becomes clear that they are used in almost every major industry. In manufacturing and assembly lines, they help move raw materials and finished products seamlessly. Warehousing and logistics companies rely on rollers to transport, sort, and distribute packages quickly.

In mining, cement, and steel plants, heavy-duty rollers are used to move bulk materials like coal, ores, and cement bags. Food and pharmaceutical industries prefer stainless steel rollers because of their hygiene and corrosion resistance. Even airports, postal services, and packaging industries use conveyor rollers to manage high volumes of goods efficiently.

The versatility of conveyor rollers is what makes them so valuable. From lightweight packaging units to large-scale plants, industries depend on them for smooth, reliable, and cost-effective operations. Knowing what are Conveyor Rollers highlights how they connect multiple sectors through a common goal—efficient material handling.

At the same time, many businesses also explore What is a Conveyor Gearbox?, since gearboxes work hand-in-hand with rollers to provide the power, torque, and speed control necessary for heavy-duty conveyor systems.

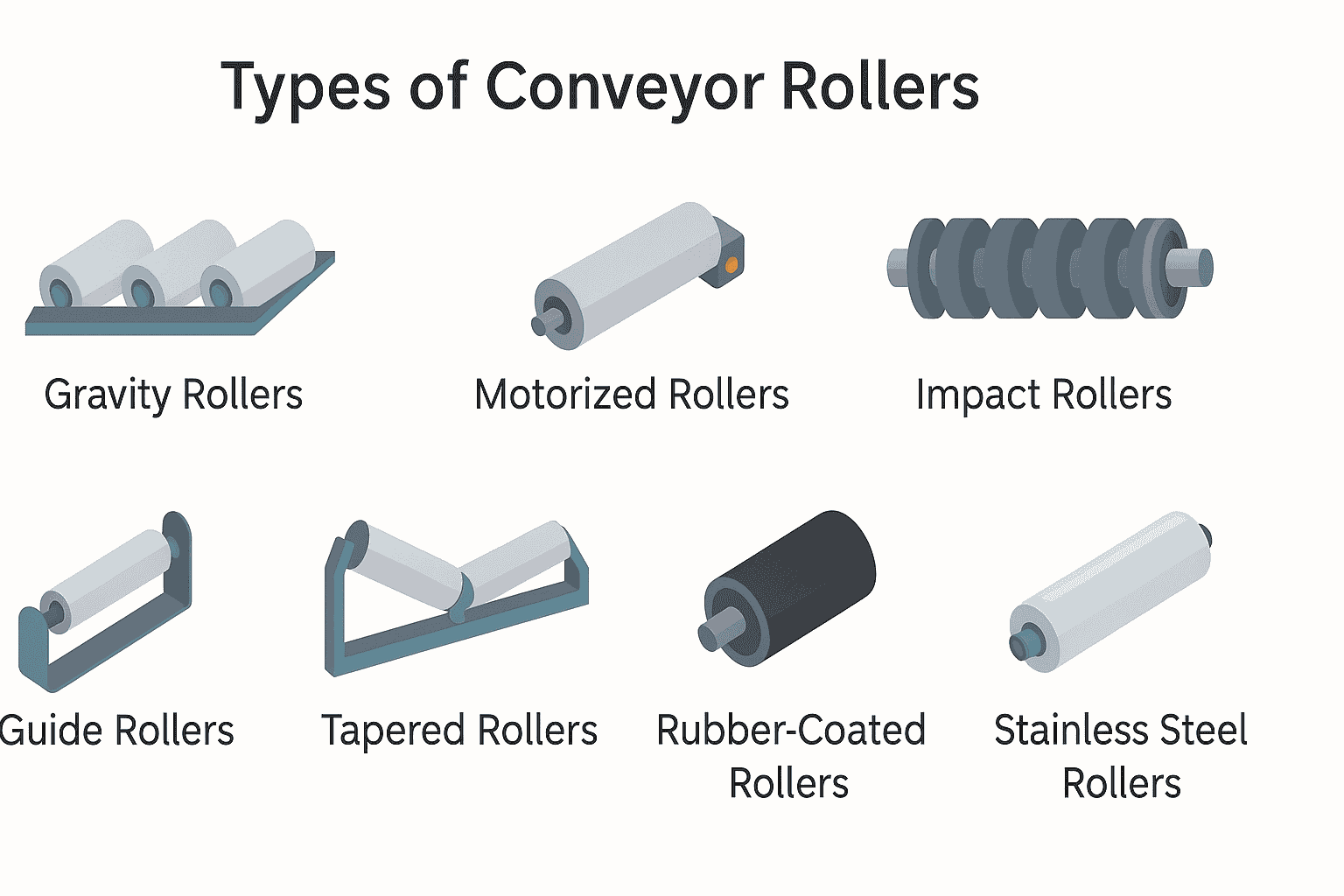

Types of Conveyor Rollers

When industries search for Types of Conveyor Rollers, they usually want to understand which roller best suits their material handling needs. Conveyor rollers are not one-size-fits-all; each type is built with a specific function in mind.

From simple gravity rollers that move lightweight packages to stainless steel rollers designed for hygiene-sensitive sectors, the variety ensures that industries can operate efficiently while reducing downtime and costs.

The main Types of Conveyor Rollers include gravity rollers, motorized rollers, impact rollers, guide rollers, tapered rollers, rubber-coated rollers, and stainless steel rollers.

Each of these plays a unique role, whether it’s handling delicate goods, aligning conveyor belts, or withstanding heavy loads in mining and cement plants. Selecting the right type improves workflow, extends equipment life, and enhances overall safety.

Much like choosing the right module in a professional training program, selecting the correct roller type directly affects long-term performance. By understanding the different Types of Conveyor Rollers, businesses can match their production needs with the right technology, ensuring smoother operations and cost savings.

1.Gravity Rollers

Gravity rollers are one of the most common Types of Conveyor Rollers. They do not use motors or electricity but instead rely on manual push or gravity for movement. This makes them highly cost-effective and energy-efficient, often used in warehouses, assembly lines, and small-scale production units.

These rollers are best suited for lightweight goods or packaging operations where speed and power are not a priority. Their simple design allows easy installation and low maintenance, making them a budget-friendly choice for industries aiming to streamline transport processes. By reducing energy usage, they also contribute to sustainability goals

2. Motorized Rollers

Motorized rollers, also called driven rollers, are advanced Types of Conveyor Rollers that use built-in motors to power continuous material flow.

They are ideal for industries that handle high volumes of goods, such as logistics centers, e-commerce warehouses, and large-scale manufacturing plants.

These rollers ensure speed, consistency, and accuracy in transporting goods, reducing dependency on manual effort. While they cost more than gravity rollers, they improve long-term efficiency and productivity.

For businesses requiring automated and uninterrupted operations, motorized rollers are a smart investment.

3. Impact Rollers

Impact rollers are specialized Types of Conveyor Rollers designed to absorb shock from heavy or sharp materials. They are typically installed at conveyor loading points in industries like mining, cement, and steel, where bulk material drops directly onto the belt.

Equipped with rubber rings, these rollers cushion the impact, preventing belt damage and reducing maintenance costs. By protecting conveyor systems, impact rollers increase durability and safety. They are crucial for heavy-duty industries where equipment protection directly affects production efficiency.

4. Guide Rollers

Guide rollers are vital Types of Conveyor Rollers used to keep conveyor belts properly aligned. A misaligned belt can cause breakdowns, product loss, and safety risks. Guide rollers solve this issue by ensuring belts stay centered during operation.

They are commonly used in industries with high-speed conveyors, such as logistics, food processing, and packaging. Proper alignment improves efficiency, reduces wear, and extends conveyor belt life. Guide rollers act as a preventive measure, saving industries from costly repairs and downtime.

5. Tapered Rollers

Tapered rollers are unique Types of Conveyor Rollers designed to handle curves in conveyor systems. Unlike straight rollers, their conical shape ensures smooth flow of goods around bends without slipping or jamming.

These rollers are widely used in airports, postal services, and large distribution centers where conveyors must navigate tight spaces. By enabling efficient handling of products in curved sections, tapered rollers improve flexibility in system design while maintaining safety and reliability.

6. Rubber-Coated Rollers

Rubber-coated rollers are practical Types of Conveyor Rollers that provide extra grip and cushioning for delicate or slippery materials. The rubber coating minimizes slippage and prevents damage to fragile items such as glass, packaged goods, or electronics.

They are also quieter and reduce vibration, making them ideal for industries needing smooth and controlled transport. Their durability and protective qualities make them a preferred choice for businesses that prioritize both product safety and conveyor longevity.

7. Stainless Steel Rollers

Stainless steel rollers are premium Types of Conveyor Rollers used in industries where hygiene and corrosion resistance are critical. Common in food processing, pharmaceuticals, and chemical industries, these rollers are resistant to rust and easy to clean.

Their robust build ensures they can handle both lightweight and heavy materials while maintaining strict hygiene standards. For industries where contamination or corrosion cannot be risked, stainless steel rollers are the most reliable option, offering both durability and compliance with safety regulations

Key Uses of Conveyor Rollers Across Industries

When businesses explore the Uses of Conveyor Rollers, it becomes clear that these components are the backbone of modern material handling systems.

Conveyor rollers are designed to move goods, raw materials, and products smoothly, reducing manual labor and ensuring efficiency in high-volume operations. Their adaptability allows them to fit into different industries, from light packaging to heavy-duty mining, making them one of the most versatile industrial tools.

The Uses of Conveyor Rollers vary depending on the industry. In manufacturing, they keep production lines moving efficiently. In warehousing, they simplify sorting and distribution. In mining and cement plants, heavy-duty rollers protect conveyor belts from wear caused by bulk materials.

Meanwhile, in food and pharmaceuticals, stainless steel rollers maintain hygiene standards. To support these operations, industries also depend on reliable Plummer Block manufacturer solutions, as plummer blocks provide the essential bearing support that ensures conveyor rollers and shafts operate smoothly under heavy loads.

By reducing downtime, improving safety, and streamlining operations, conveyor rollers not only enhance productivity but also save costs for businesses. Their ability to handle both lightweight and heavy-duty applications proves that they are not just simple mechanical parts, but critical assets for industries worldwide. Understanding the Uses of Conveyor Rollers highlights their importance in ensuring long-term industrial growth.

1. Manufacturing and Assembly Lines

One of the primary Uses of Conveyor Rollers is in manufacturing and assembly lines. Here, rollers help move raw materials, semi-finished products, and finished goods seamlessly across different stages of production. Whether it is in automobile plants, electronics factories, or packaging units, conveyor rollers ensure continuous workflow without interruptions.

By maintaining a steady movement of goods, rollers reduce delays, improve accuracy, and increase output. They also minimize manual handling, which lowers the risk of errors and workplace injuries.

In modern assembly lines where speed and precision are crucial, conveyor rollers are indispensable. Their role in streamlining operations directly translates to higher productivity and efficiency.

2. Warehousing and Distribution Centers

Another significant area where the Uses of Conveyor Rollers stand out is in warehousing and distribution. Large-scale facilities often deal with thousands of packages daily, and rollers make the movement, sorting, and dispatch of these goods much faster.

Gravity rollers are commonly used in these settings for cost-effective transport, while motorized rollers help in automated systems for high-volume operations. By integrating rollers, warehouses reduce labor costs and ensure faster order fulfillment.

In today’s e-commerce-driven economy, conveyor rollers have become essential in managing logistics efficiently and meeting customer demands on time.

3. Mining, Cement, and Heavy Industries

Heavy-duty Uses of Conveyor Rollers can be seen in mining, cement, and steel plants, where they carry bulk materials like coal, ores, and cement bags. These industries require rollers that can withstand heavy loads and harsh environments. Impact rollers and rubber-coated rollers are often used at loading points to protect conveyor belts from damage.

By ensuring smooth transport of heavy materials, rollers reduce wear and tear, extend equipment life, and minimize downtime. In industries where equipment breakdowns can cause huge losses, the reliability of conveyor rollers plays a crucial role in maintaining productivity and safety.

4. Food Processing and Pharmaceutical Industries

The Uses of Conveyor Rollers in food and pharmaceutical industries focus on hygiene, safety, and efficiency. Stainless steel rollers are widely used because they are corrosion-resistant, easy to clean, and compliant with strict health standards. They ensure that products such as packaged food, medicines, or medical equipment are transported safely without contamination.

These rollers also withstand frequent washdowns and temperature variations, making them suitable for sensitive environments.

By maintaining both cleanliness and efficiency, conveyor rollers help these industries meet regulatory requirements while ensuring smooth operations. Their role in food and pharma highlights the importance of specialized roller types tailored to industry needs.

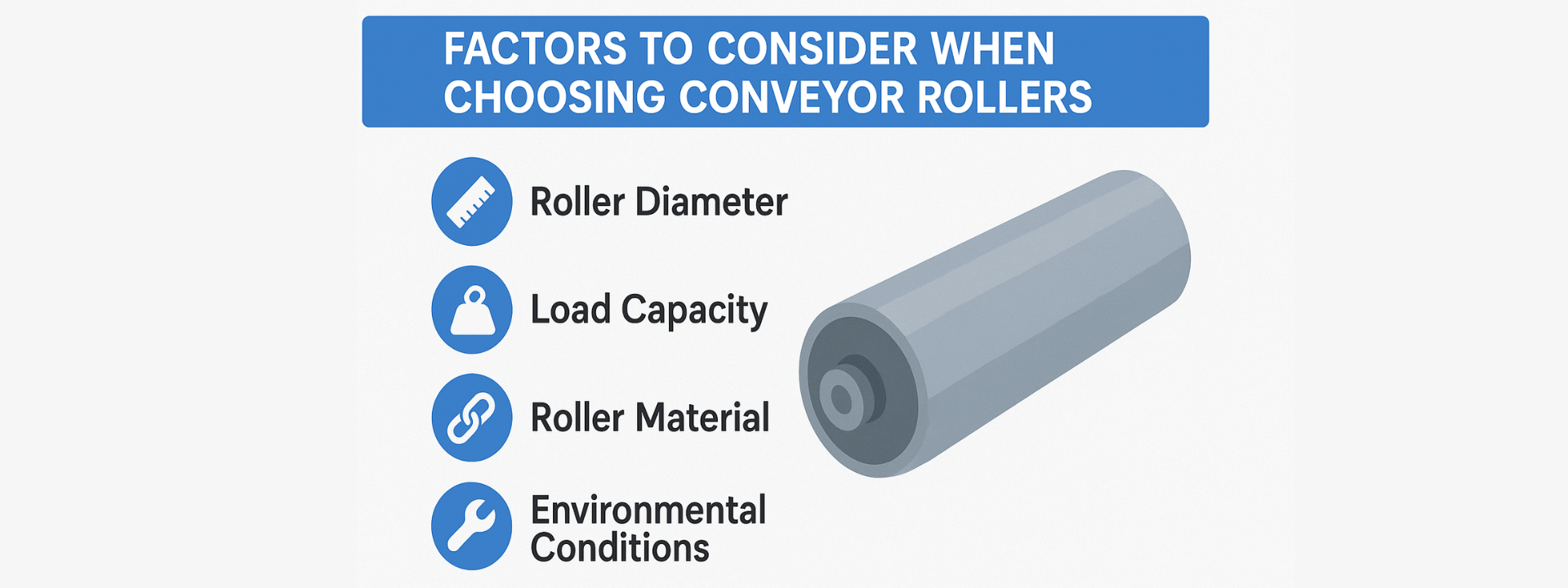

Factors to Consider When Choosing Conveyor Rollers

Selecting the right Conveyor Rollers is critical for ensuring smooth and efficient operations across industries. While rollers may look similar, their design, material, and specifications can significantly affect performance and durability.

Choosing the wrong type can lead to increased downtime, higher maintenance costs, and even damage to conveyor systems. That’s why businesses must carefully evaluate key factors before making a decision.

The most important considerations include the load capacity and material of the roller, as these directly impact how well it handles the products being transported. Speed, noise levels, and energy efficiency are also crucial, especially in industries where conveyors run continuously. Additionally, maintenance requirements and overall longevity determine the long-term value of the rollers.

By analyzing these factors, companies can match their production needs with the right roller type, whether for lightweight goods in packaging units or heavy-duty loads in mining and cement plants.

In short, understanding what to look for in Conveyor Rollers ensures better performance, safety, and cost-effectiveness in any industrial setup.

1. Load Capacity and Roller Material

When selecting Conveyor Rollers, the first consideration should be load capacity and roller material. Rollers must be able to support the weight of the goods being transported without bending or wearing out quickly. For light loads, plastic or aluminum rollers are sufficient, while steel or stainless steel rollers are more suitable for heavy-duty applications like mining or cement plants.

The roller material also determines durability and resistance to environmental factors. Stainless steel rollers, for example, are ideal for food and pharmaceutical industries due to their hygiene and corrosion resistance.

Choosing the right combination of load capacity and material ensures smooth performance, minimizes downtime, and extends the life of both the rollers and the conveyor system.

2. Speed, Noise, and Energy Efficiency

Another factor to evaluate when choosing Conveyor Rollers is speed, noise, and energy efficiency. In high-speed operations such as logistics and e-commerce, rollers must maintain consistent movement without creating excessive noise. Low-noise rollers improve the working environment while ensuring smooth handling of goods.

Energy efficiency is equally important for businesses running conveyors around the clock. Motorized rollers designed with efficient power consumption can help reduce operational costs over time.

By balancing speed, noise control, and energy usage, companies can achieve both productivity and cost savings. This makes roller selection a strategic decision for long-term success.

3. Maintenance and Longevity

Maintenance and longevity are essential when investing in Conveyor Rollers. Rollers that require frequent servicing can lead to production delays and higher costs. Opting for durable rollers with low-maintenance designs ensures consistent performance and minimizes downtime.

Industries like mining, warehousing, and food processing demand rollers that can withstand continuous use and harsh conditions. High-quality rollers not only last longer but also protect conveyor belts and reduce replacement expenses.

By prioritizing longevity and easy maintenance, businesses gain long-term reliability, ensuring that their conveyor systems run smoothly without costly interruptions.

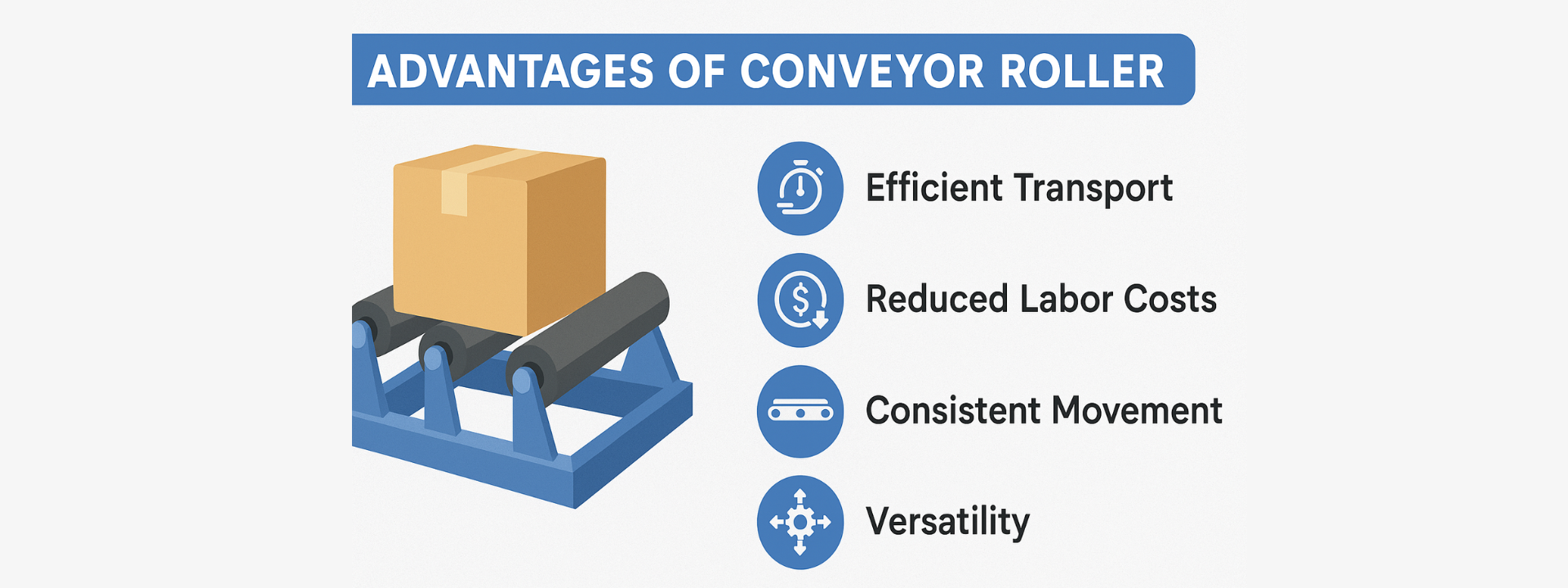

Advantages of Conveyor Rollers

When industries evaluate material handling solutions, the Advantages of Conveyor Roller quickly become evident. Conveyor rollers are essential components in modern systems, enabling the smooth, reliable, and cost-effective transport of goods.

Their simple yet powerful design makes them suitable for a wide range of industries, from warehousing and logistics to mining and pharmaceuticals.

One of the biggest Advantages of Conveyor Roller is efficiency. By reducing manual labor and streamlining processes, rollers allow businesses to handle larger volumes of materials with speed and accuracy. This translates directly into improved productivity and higher output. Another benefit is cost savings—rollers require less energy compared to fully automated machinery and have relatively low maintenance needs.

They also improve workplace safety by minimizing the need for heavy lifting and providing smoother handling of delicate goods. Whether it’s preventing production bottlenecks, reducing downtime, or maintaining hygiene in sensitive sectors, conveyor rollers are built to deliver long-term value.

In short, the Advantages of Conveyor Roller extend far beyond moving materials. They contribute to efficiency, safety, and reliability, making them an indispensable part of industrial operations worldwide.

1. Improved Efficiency and Productivity

One of the core Advantages of Conveyor Roller is its ability to boost efficiency and productivity. By automating material transport, rollers reduce reliance on manual labor and ensure a steady flow of goods across production lines or warehouses. This helps industries process larger volumes in less time.

Because rollers enable smooth and consistent movement, delays and bottlenecks are minimized. For businesses, this means faster turnaround times, better resource utilization, and increased competitiveness. Ultimately, improved efficiency translates into higher profitability and growth opportunities.

2. Reduced Downtime and Maintenance Costs

Another major Advantage of Conveyor Roller is its low maintenance requirement. Unlike complex machinery, rollers have a simple design with fewer moving parts, which reduces the chances of breakdowns. As a result, industries experience less downtime, keeping operations running smoothly.

High-quality rollers are built for durability and can withstand continuous use in demanding environments. This reliability reduces repair costs and extends equipment life. For businesses, the combination of durability and reduced maintenance means long-term cost savings, making conveyor rollers a smart investment.

3. Safer and Smoother Operations

afety and reliability are also key Advantages of Conveyor Roller. By reducing manual lifting and carrying, rollers lower the risk of workplace injuries. They provide controlled, stable transport, ensuring even fragile goods are handled safely without damage.

In industries such as food processing and pharmaceuticals, rollers also support compliance with hygiene and safety standards. Their ability to deliver smoother operations protects both workers and products, while maintaining efficiency.

This balance of safety and performance makes conveyor rollers a trusted solution across diverse sectors.

Conclusion

Selecting the right Conveyor Roller is more than just a technical decision—it is a strategic investment that directly impacts efficiency, safety, and long-term profitability. Every industry, whether it is manufacturing, logistics, mining, or food processing, depends on the smooth movement of goods, and the type of roller chosen can make all the difference.

The best Conveyor Roller for your needs depends on key factors such as load capacity, speed requirements, working environment, and maintenance preferences.

For light packaging or assembly lines, gravity rollers may be sufficient, while motorized rollers are better suited for high-speed warehouses. Impact rollers are essential in heavy industries like mining, and stainless steel rollers ensure hygiene and durability in sensitive sectors such as food and pharmaceuticals.

Beyond technical specifications, businesses should also focus on long-term value. A high-quality Conveyor Roller not only minimizes downtime but also reduces maintenance costs and enhances workplace safety. By choosing the right roller type that matches operational needs, companies can achieve smoother workflows and consistent performance.

Partnering with a trusted Conveyor Gearbox manufacturing company further ensures durability, efficiency, and reliability in material handling systems.

In conclusion, understanding your industry needs and aligning them with the right Conveyor Roller guarantees not only operational efficiency but also sustainable growth. Making an informed choice today will save costs, protect equipment, and enhance productivity for years to come.

FAQS

What is the best material for conveyor rollers?

The best material for conveyor rollers depends on the application. For heavy-duty industries like mining, steel rollers are preferred for their strength. Stainless steel rollers are widely used in food and pharmaceutical sectors for hygiene and corrosion resistance, while plastic or PVC rollers suit lightweight packaging due to their cost-effectiveness and quiet operation. Nisuka Industries provides durable conveyor solutions that ensure smooth transport, efficiency, and reduced maintenance costs.

How many types of idler for conveyor?

There are several types of idlers used in conveyor systems, each serving a unique purpose. Common types include carrying idlers, return idlers, impact idlers, training idlers, and transition idlers. Carrying idlers support the loaded belt, while return idlers guide the empty belt back. Impact idlers protect the belt at loading points, and training idlers help maintain alignment. The choice of idler depends on the industry, material load, and operational requirements of the conveyor system.

How to measure a conveyor roller?

To measure a conveyor roller, start by checking the roller’s overall length, also known as the shaft end-to-end measurement. Then, measure the roller diameter, which determines the roller size. It’s also important to note the shaft diameter and the type of bearings used. Accurate measurement ensures that replacement rollers fit perfectly and function efficiently within the conveyor frame. Proper sizing helps maintain smooth material handling and prevents operational issues in conveyor systems.

How to control conveyor speed?

Conveyor speed can be controlled using several methods depending on the system type. Variable Frequency Drives (VFDs) are commonly used in motorized conveyors to adjust motor speed. Mechanical gearboxes and adjustable pulleys are also effective in controlling speed. For gravity conveyors, the slope angle influences the roller speed. Maintaining proper speed ensures safe handling, prevents product damage, and improves efficiency. Speed control is especially important in industries where accuracy and timing are critical.

What is the principle of conveyor?

The basic principle of a conveyor is to transport materials smoothly and efficiently from one point to another using rollers, belts, or chains. It reduces manual labor by automating movement and ensures consistent workflow. Rollers or belts support the material, while motorized systems or gravity provide motion. This principle is applied in various industries like manufacturing, logistics, mining, and food processing. Conveyors are designed to save time, increase efficiency, and improve workplace safety.

How many types of pulley are in a conveyor?

Conveyor systems use different pulleys depending on function. The most common are head pulleys, which drive the conveyor belt, and tail pulleys, which provide tension and return the belt. Snub pulleys increase belt wrap around the head pulley, improving grip, while bend pulleys change the belt’s direction. Take-up pulleys maintain proper tension. Each type of pulley is designed to enhance belt performance and ensure smooth, efficient operation across various industrial conveyor systems.

What type of bearings are used in a roller conveyor?

Roller conveyors typically use ball bearings or tapered roller bearings. Ball bearings are common in light- to medium-duty rollers as they allow smooth rotation and reduce friction. Tapered roller bearings are preferred for heavy-duty applications, as they can handle both radial and axial loads. Sealed bearings are often used to protect against dust and moisture in harsh environments. The choice of bearing directly affects the performance, durability, and maintenance needs of conveyor rollers.