What is a Shaft Mounted Gearbox? Complete Guide

modern industrial machinery, efficient power transmission plays a critical role in ensuring productivity, reliability, and long-term performance. One of the most widely used solutions for torque transmission in conveyor systems, material handling equipment, mining operations, and manufacturing plants is the shaft mounted gearbox. Designed for direct mounting onto a driven shaft, this type of gearbox eliminates the need for complex alignment processes, making installation simpler while improving operational efficiency.

Engineers and maintenance professionals often prefer shaft mounted gearboxes due to their compact design, high torque capacity, and reduced maintenance requirements. However, selecting the right gearbox requires a clear understanding of its working principle, advantages, applications, and key selection parameters. With increasing industrial automation and demand for energy-efficient machinery in India and globally, understanding how shaft mounted gearboxes function has become essential for machine builders, plant managers, and purchasing teams.

Additionally, industries that rely on material handling and magnetic separation systems — such as a Suspension Magnet manufacturer — often integrate efficient power transmission solutions like shaft mounted gearboxes to ensure reliable performance and optimized operational efficiency

In this complete guide, we will explore everything you need to know — from basic definitions and working mechanisms to practical applications, benefits, installation insights, and expert tips for choosing the right shaft mounted gearbox for your industrial needs. Whether you are a beginner or an experienced professional, this guide aims to provide clear, practical, and reliable information

What is a Shaft Mounted Gearbox?

A shaft mounted gearbox is a type of industrial speed reducer designed to be directly installed onto the driven shaft of a machine, eliminating the need for complex base mounting or coupling arrangements.

When understanding What is a Shaft Mounted Gearbox, it is important to know that this gearbox is mainly used to reduce speed while increasing torque, allowing machinery to operate efficiently under heavy load conditions. Because of its compact design and easy installation process, it has become a popular solution across many industries such as mining, material handling, agriculture, and manufacturing.

In simple terms, the answer to What is a Shaft Mounted Gearbox lies in its unique mounting system. Instead of being fixed separately on a foundation, the gearbox sits directly on the output shaft. This design reduces alignment issues, saves installation time, and minimizes maintenance requirements. Many engineers prefer this system because it provides reliable power transmission while reducing space usage in industrial setups.

The working principle involves transmitting power from a motor through internal gears that reduce rotational speed and increase torque output. As a result, machines like conveyors, crushers, and processing equipment can operate smoothly and safely. Key features include a hollow shaft design, torque arm support, and durable housing built for harsh industrial environments.

When people ask What is a Shaft Mounted Gearbox, they often want a solution that offers efficiency, durability, and cost-effective performance. Its simple installation, reduced vibration, and high load capacity make it an ideal choice for applications where reliability is critical.

Choosing a reliable Shaft mounted Gearbox manufacturer also ensures consistent quality, proper engineering support, and long-term operational performance. Overall, this gearbox plays an essential role in modern industrial systems by improving operational efficiency and reducing downtime.

Types of Shaft Mounted Gearboxes

Understanding the Types of Shaft Mounted Gearboxes is essential for selecting the right power transmission solution for industrial applications. These gearboxes are designed to mount directly onto a driven shaft, which simplifies installation, reduces alignment issues, and improves overall efficiency. Different industries such as mining, cement, material handling, and manufacturing use various designs based on torque requirements, speed reduction needs, and operating environments.

Knowing the main Types of Shaft Mounted Gearboxes helps engineers and buyers make informed decisions that improve machine reliability and performance.

1. SMSR (Shaft Mounted Speed Reducer)

One of the most commonly used options among the Types of Shaft Mounted Gearboxes is the SMSR gearbox. It is widely used in conveyor systems and bulk material handling because of its simple design, high torque capacity, and easy maintenance. SMSR units typically use helical gears that provide efficient power transmission and smooth operation.

The torque arm design helps support reaction forces, making installation quick and reliable. Understanding What Is SMSR Gearbox helps engineers and buyers select the right configuration based on load requirements, operating conditions, and overall system efficiency.

2. Helical Shaft Mounted Gearbox

Helical shaft mounted gearboxes are known for their high efficiency and quiet operation. Among the popular Types of Shaft Mounted Gearboxes, this design uses angled teeth that allow gradual engagement between gears, reducing vibration and noise. These gearboxes are suitable for continuous-duty applications where reliability and energy efficiency are important, such as packaging lines, processing plants, and automated systems.

3. Planetary Shaft Mounted Gearbox

Planetary designs are advanced Types of Shaft Mounted Gearboxes that offer compact size with high torque output. They distribute load across multiple gears, which increases strength and improves durability. This type is ideal for heavy-duty applications where space is limited but high performance is required.

4. Parallel Shaft vs Hollow Shaft Gearboxes

Parallel shaft and hollow shaft designs are two structural variations within the Types of Shaft Mounted Gearboxes. Parallel shaft gearboxes are suitable for applications needing precise alignment, while hollow shaft models allow direct mounting on the shaft, reducing components and simplifying installation.

Common Applications of Shaft Mounted Gearboxes

The Applications of Shaft Mounted Gearboxes are widely seen across industries that require reliable torque transmission, efficient speed reduction, and simple installation. These gearboxes are directly mounted onto the driven shaft, making them ideal for heavy-duty industrial environments where durability and performance are critical. Because of their compact design and reduced alignment requirements, many engineers prefer shaft mounted gearboxes for continuous operations.

Understanding the main Applications of Shaft Mounted Gearboxes helps businesses select the right equipment to improve productivity and reduce maintenance costs.

1. Conveyor Systems

One of the most common Applications of Shaft Mounted Gearboxes is in conveyor systems used for transporting materials across industrial facilities. Industries such as logistics, food processing, packaging, and manufacturing rely on conveyors for smooth and continuous movement. Shaft mounted gearboxes provide consistent torque and reliable operation, which ensures efficient material flow while minimizing downtime.

2. Mining and Quarry Equipment

Mining and quarry operations require equipment that can handle heavy loads and harsh environments. Among the major Applications of Shaft Mounted Gearboxes, mining machinery such as crushers, feeders, and belt conveyors benefit from their strong construction and ability to manage high torque. These gearboxes improve efficiency while reducing the risk of mechanical failure.

3. Cement and Steel Industry

The cement and steel industries depend on heavy machinery that operates under extreme conditions. The Applications of Shaft Mounted Gearboxes in these sectors include rotary kilns, conveyor belts, mixers, and material handling equipment. Their robust design ensures stable performance even under continuous load and high temperatures.

4. Agriculture and Bulk Material Handling

Agricultural equipment and bulk material handling systems also represent important Applications of Shaft Mounted Gearboxes. They are used in grain elevators, augers, and feed processing machines where easy installation and reliable power transmission are essential for smooth operation.

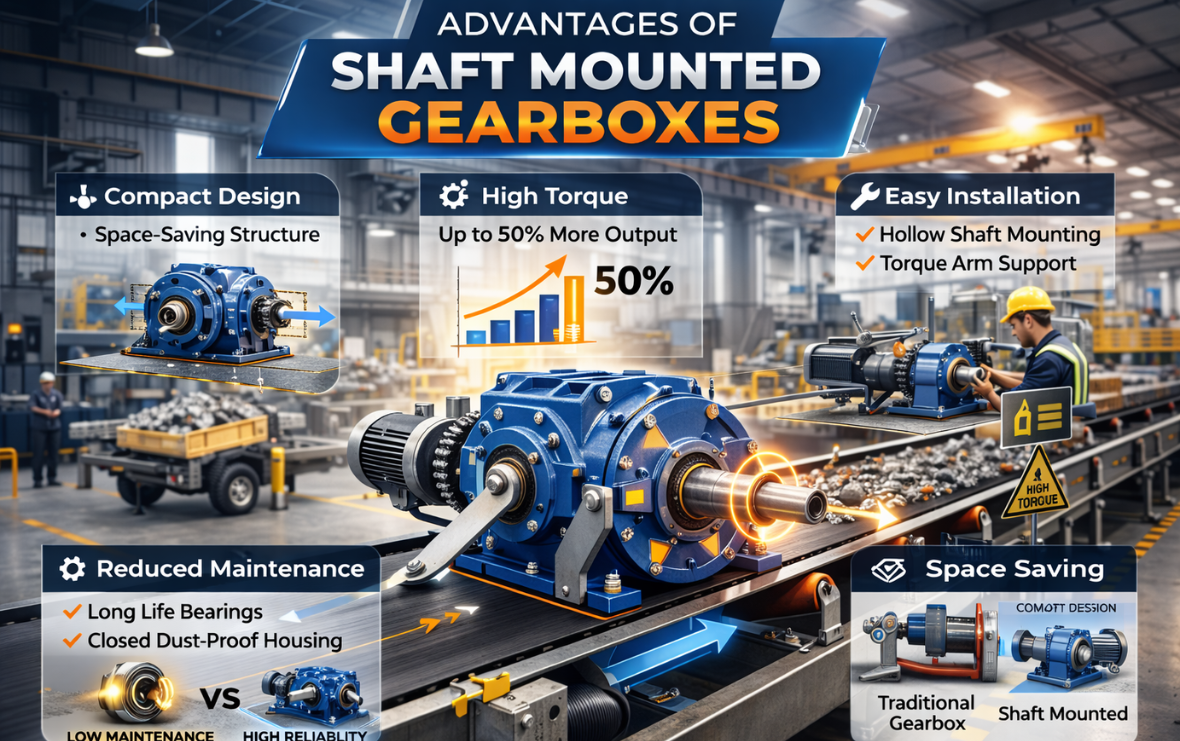

Advantages of Shaft Mounted Gearboxes

The Advantages of Shaft Mounted Gearboxes make them a highly preferred solution in modern industrial power transmission systems. These gearboxes are specially designed to mount directly onto the driven shaft, which reduces the need for complex mounting structures and simplifies the overall installation process.

Because industries today focus on efficiency, reliability, and cost optimization, understanding the key Advantages of Shaft Mounted Gearboxes helps engineers and business owners select equipment that improves performance while reducing operational challenges.

1. Compact Design and Easy Installation

One of the main Advantages of Shaft Mounted Gearboxes is their compact and space-saving design. Unlike traditional gearboxes that require additional base plates and alignment setups, shaft mounted units can be installed directly onto the shaft. This reduces installation time and minimizes the chances of alignment errors. The simplified mounting system also makes them ideal for applications where space is limited or where quick installation is required.

2. High Torque Transmission Efficiency

Another important factor among the Advantages of Shaft Mounted Gearboxes is their ability to transmit high torque efficiently. These gearboxes are designed to handle heavy loads while maintaining smooth and consistent power transfer. This improves machine performance and helps reduce energy losses, making them suitable for conveyor systems, crushers, and heavy-duty industrial equipment.

3. Reduced Maintenance Requirements

Reduced maintenance is a key benefit that highlights the practical Advantages of Shaft Mounted Gearboxes. Since fewer external components and couplings are involved, there is less wear and tear. This leads to fewer breakdowns, easier inspection, and longer service life, which is especially important in continuous production environments.

4. Cost Benefits Compared to Traditional Gearboxes

Cost savings are another major reason industries consider the Advantages of Shaft Mounted Gearboxes. Lower installation costs, reduced downtime, and minimal maintenance needs contribute to long-term financial benefits compared to traditional gearbox systems.

Final Thoughts

In conclusion, understanding What is a Shaft Mounted Gearbox? Complete Guide helps engineers, buyers, and industry professionals make smarter decisions when selecting power transmission equipment. A shaft mounted gearbox is designed to provide efficient speed reduction and high torque output while simplifying installation through direct mounting on the driven shaft. This unique design reduces alignment issues, saves space, and improves overall machine reliability, making it a preferred choice across industries such as material handling, mining, cement, agriculture, and manufacturing.

Throughout this guide, we explored the basic concept, working principle, types, applications, and advantages of shaft mounted gearboxes. Each section highlights how these gearboxes contribute to smoother operation, reduced maintenance requirements, and long-term cost savings. As industries continue moving toward automation and energy-efficient machinery, choosing components that enhance productivity and reliability becomes essential. Understanding What is Conveyor Magnet technology alongside efficient drive solutions can further improve material handling efficiency, system safety, and overall operational performance.

When evaluating options, it is important to consider factors such as torque capacity, gear ratio, installation environment, and maintenance needs. Proper selection ensures better performance and extends equipment lifespan. Ultimately, knowing What is a Shaft Mounted Gearbox allows businesses to optimize their machinery and reduce operational risks.

FAQS

What is the difference between shaft mounted gearbox and flange mounted gearbox?

A shaft mounted gearbox is installed directly onto the driven shaft, while a flange mounted gearbox is attached using a flange connection. Shaft mounted designs reduce alignment issues and installation time, whereas flange mounted gearboxes provide more structural support in fixed-position applications.

What materials are used to manufacture shaft mounted gearboxes?

Most shaft mounted gearboxes are made from high-grade cast iron or steel housings with hardened alloy steel gears. These materials provide strength, durability, and resistance to wear, allowing the gearbox to operate efficiently in heavy-duty industrial environments.

Can shaft mounted gearboxes handle heavy loads?

Yes, shaft mounted gearboxes are designed for high torque and heavy load applications. Their robust construction and efficient gear design allow them to perform reliably in demanding industries such as mining, cement production, and bulk material handling.

How do you maintain a shaft mounted gearbox?

Regular lubrication checks, oil level monitoring, inspection for leaks, and proper alignment verification help maintain performance. Scheduled maintenance prevents overheating and wear, ensuring longer service life and consistent operation in industrial conditions.

What lubrication is used in shaft mounted gearboxes?

Most shaft mounted gearboxes use industrial-grade gear oil designed for high load and temperature conditions. Proper lubrication reduces friction between gears, prevents overheating, and improves overall efficiency and durability.