What is the Difference Between a Pillow Block and a Plummer Block?

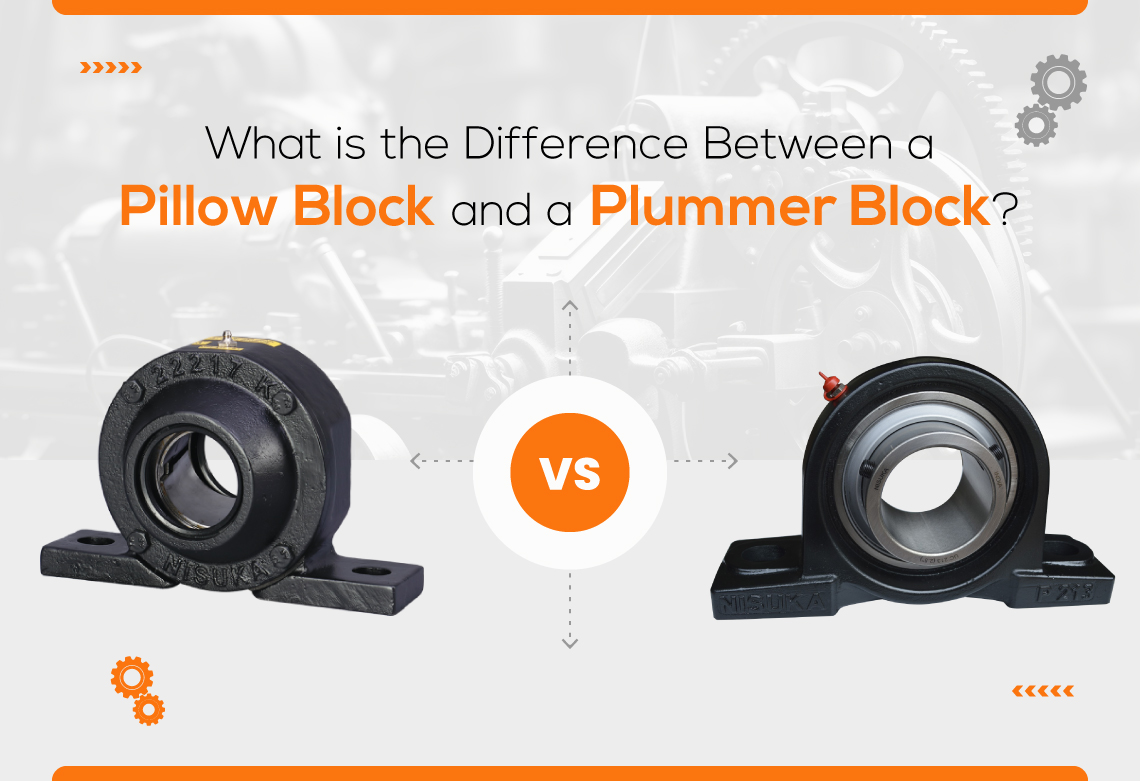

In industrial machinery, smooth operation and long-lasting performance often depend on the right type of bearing housing. Two of the most commonly used bearing supports are the Pillow Block and the Plummer Block. While they may look similar at first glance, these components have distinct structural and functional differences that can significantly affect machine efficiency, durability, and maintenance needs.

Many engineers, plant operators, and procurement teams often wonder: Which one is better for my application—a Pillow Block or a Plummer Block? The answer lies in understanding their design, load capacity, and installation requirements.

Pillow Blocks are generally used for lighter loads and simpler setups, while Plummer Blocks are engineered for heavier loads and more demanding environments.

By choosing the right bearing housing, industries can reduce downtime, enhance operational safety, and achieve cost-effective performance. In this guide, we will break down the key differences between Pillow Blocks and Plummer Blocks, explore their unique advantages, and help you decide which option is the right fit for your machinery. Whether you are upgrading equipment or planning a new installation, knowing these differences will help you make a smarter, more informed decision. For reliable solutions, consulting a trusted Plummer Block manufacturer can also ensure you get the right product for your industrial needs.

Whether you are upgrading equipment or planning a new installation, knowing these differences will help you make a smarter, more informed decision.

Common Industrial Applications of Pillow & Plummer Blocks

Pillow Blocks are widely used in applications like conveyors, agricultural machinery, packaging equipment, and light-duty fans. Their compact structure and ease of installation make them a preferred choice for systems with moderate loads.

Plummer Blocks are common in industries such as mining, steel manufacturing, marine operations, and heavy-duty conveyors—anywhere high loads, harsh environments, and continuous operation are involved. By matching the right bearing housing to the application, industries can enhance efficiency, minimize breakdowns, and extend equipment lifespan.

Key Design Differences Pillow Blocks and Plummer Blocks

While both Pillow Blocks and Plummer Blocks serve the same primary function—housing and supporting a bearing—their design differences greatly influence performance, installation, and durability.

These variations make each type better suited for specific industrial applications.

1.Construction and Material Variations

Pillow Blocks are typically a single-piece housing with a flat mounting base. They are compact, lightweight, and often made from cast iron, pressed steel, or thermoplastic materials, depending on the application.

Plummer Blocks, in contrast, have a split housing design, allowing the top half to be removed for easy inspection and maintenance without disassembling the shaft. They are generally made from heavy-duty cast iron or cast steel to handle demanding environments and higher loads.

2.Bearing Mounting and Alignment

In Pillow Blocks, the bearing is pre-mounted inside the housing, making installation simple and quick. They are bolted directly to a surface, requiring minimal alignment. Plummer Blocks, however, require more precise installation.

The bearing is mounted separately inside the housing, giving flexibility to adjust alignment and accommodate shaft expansion. This makes them ideal for long shafts and systems where precision is critical.

3.Load and Speed Handling Capabilities

Pillow Blocks are designed for moderate loads and speeds, making them perfect for light to medium-duty applications. Plummer Blocks excel in heavy-duty conditions, supporting higher radial and axial loads.

Their robust construction, combined with effective lubrication systems, allows them to perform reliably under continuous, high-speed operations in industries like mining, steel, and marine engineering.

Functional Comparison Between Pillow Blocks and Plummer Blocks

While Pillow Blocks and Plummer Blocks may look similar, their functionality is tailored to different operational demands.

Both house bearings to support rotating shafts, but the way they operate, the environments they suit, and their performance capabilities differ significantly.

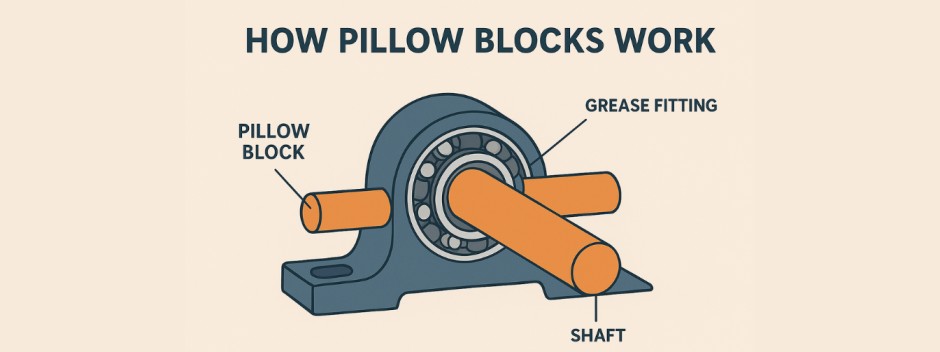

How Pillow Blocks works

Pillow Blocks are designed as a single-piece housing unit with a bearing pre-installed. They are mounted on a flat surface, allowing quick setup without complex alignment. The bearing within the housing provides smooth shaft rotation while reducing friction and wear.

These units typically have seals to protect against dust and mild contaminants, making them well-suited for moderate-load applications such as conveyors, agricultural machines, and light manufacturing equipment. Their straightforward design means minimal maintenance and easy replacement when needed.

How Plummer Blocks works

Plummer Blocks feature a split housing design, allowing the top section to be removed for bearing inspection or replacement without dismantling the shaft. The bearing is mounted separately, giving more flexibility in alignment and fit.

These housings are built to handle heavy radial and axial loads, often with advanced sealing and lubrication options for harsh environments. They are widely used in steel plants, mining operations, and heavy-duty conveyors where long-term reliability is essential. For high-quality solutions, partnering with a trusted UCP Pillow Block manufacturer ensures durability and consistent performance in demanding applications.

Which One Offers Better Performance Pillow Blocks or Plummer Blocks

Performance depends on the application. Pillow Blocks excel in light to medium-duty operations where ease of installation and low maintenance are priorities.

Plummer Blocks outperform in demanding industrial settings, offering superior load capacity, durability, and adaptability. The “better” choice ultimately comes down to matching the bearing housing to the operational requirements, load conditions, and environmental factors.

Advantages and Disadvantages Between Pillow Blocks and Plummer Blocks

Selecting between Pillow Block and Plummer Block bearings requires understanding not only their capabilities but also their limitations.

Each has specific benefits that make it better suited for certain machinery and operational conditions.

Benefits of Pillow Blocks

Pillow Block bearings are valued for their simplicity and ease of installation. They come as a single-piece housing with a pre-mounted bearing, reducing setup time and minimizing the need for precise alignment.

Their compact size makes them ideal for applications with space constraints, such as conveyor systems, agricultural equipment, and packaging machines. They are cost-effective, require minimal maintenance, and can be easily replaced when worn out, making them a practical choice for light to medium-duty applications.

Benefits of Plummer Blocks

Plummer Block bearings are designed for heavy-duty performance. Their split housing design allows easy inspection, lubrication, and bearing replacement without removing the shaft.

When understanding what is Plummer Block, it is important to note that these units are made from robust materials like cast iron or cast steel. They can withstand higher radial and axial loads, operate in harsh environments, and handle longer operational cycles. This makes them ideal for industries such as mining, steel production, and marine operations, where reliability and load capacity are critical.

Limitations of Pillow Blocks and Plummer Blocks

Pillow Blocks are not suitable for extremely high loads or harsh environmental conditions, as their simpler construction limits strength and sealing efficiency. Plummer Blocks, while more durable, require precise installation and are generally more expensive.

They may also be bulkier, making them unsuitable for compact machinery layouts. Understanding these trade-offs ensures that the chosen bearing housing delivers maximum performance and longevity in its intended application.

Choosing the Right Bearing Unit for Your Application

Selecting between a Pillow Block and a Plummer Block is not just a matter of preference—it’s about matching the right bearing housing to your machine’s operational needs.

The correct choice can improve efficiency, reduce maintenance costs, and extend equipment life.

1.Factors to Consider (Load, Environment, Maintenance)

The first step is evaluating the load requirements. Pillow Blocks are best suited for light to medium loads, while Plummer Blocks are designed for heavy radial and axial forces.

Next, consider the operating environment. For clean, indoor settings with minimal contamination, a Pillow Block offers a cost-effective and efficient solution.

However, if the machinery operates in dusty, wet, or high-temperature conditions, a Plummer Block’s robust construction and enhanced sealing systems provide better protection. Maintenance needs are another factor—Pillow Blocks require minimal upkeep, whereas Plummer Blocks allow for easier inspection and bearing replacement without dismantling the shaft.

2.Cost and Longevity Considerations

Budget constraints play a key role in selection. Pillow Blocks are generally less expensive and quicker to install, making them ideal for cost-sensitive projects.

However, in the long run, if your application involves high loads or challenging conditions, Plummer Blocks may prove more economical due to their durability and reduced downtime.

Longevity depends on proper installation, regular lubrication, and using the correct bearing type for the load and speed. While Pillow Blocks can last many years in moderate-duty environments, Plummer Blocks are built to withstand continuous, heavy-duty operations over extended periods.

Conclusion

Understanding the differences between a Pillow Block and a Plummer Block is essential for selecting the right bearing housing for your machinery. While both serve the purpose of supporting and protecting bearings, their construction, performance capabilities, and suitability for various environments differ significantly.

Pillow Blocks excel in applications where ease of installation, compact size, and low maintenance are priorities. They are ideal for light to medium-duty operations, offering reliable performance at a cost-effective price point. Just like an SMSR Gearbox ensures smooth power transmission in heavy-duty setups, Pillow Blocks provide dependable support for rotating shafts in lighter applications.

On the other hand, Plummer Blocks are the preferred choice for heavy-duty industries, thanks to their robust construction, higher load capacity, and ease of servicing in demanding conditions.

Choosing the right option involves assessing load requirements, environmental factors, maintenance accessibility, and budget considerations. By making an informed decision, you can improve equipment efficiency, extend bearing life, and reduce costly downtime.

Whether your application calls for the simplicity of a Pillow Block or the strength of a Plummer Block, selecting the correct bearing unit ensures optimal performance and long-term value for your investment. In the end, the best choice is the one that perfectly aligns with your operational needs and performance expectations.

FAQS

What is a pillow block used for?

A pillow block is used to support a rotating shaft while maintaining alignment and reducing friction. It houses a mounted bearing inside a single-piece casing, making installation simple and quick. Pillow blocks are commonly used in conveyors, agricultural machinery, fans, and light manufacturing equipment. They provide reliable performance in moderate-load applications and protect the bearing from contaminants, ensuring smooth operation and longer service life in various industrial and mechanical systems. For industries seeking trusted quality, Nisuka Industries is best known for delivering durable and efficient pillow block solutions.

What is another name for a Plummer block?

Another name for a plummer block is a pedestal bearing. It refers to the same bearing housing design used to support rotating shafts in heavy-duty machinery. The term “plummer block” is widely used in the UK and Commonwealth countries, while “pedestal bearing” is more common in some other regions. Both describe a split-housing unit that allows easy bearing inspection, lubrication, and replacement without dismantling the shaft, making it ideal for demanding industrial applications.

What is the use of plummer blocks?

Plummer blocks are used to support heavy rotating shafts in machinery while allowing smooth, low-friction movement. They are designed for heavy-duty applications where high radial and axial loads are common. Industries such as mining, steel production, marine, and manufacturing rely on plummer blocks for durability, ease of maintenance, and long-term performance. Their split housing design allows quick bearing replacement and lubrication, minimizing downtime and ensuring operational efficiency in challenging working environments.

Can plummer blocks handle heavy loads?

Yes, plummer blocks are specifically designed to handle heavy loads. Made from robust materials like cast iron or cast steel, they can withstand high radial and axial forces. Their design includes advanced sealing systems to protect against dust, water, and other contaminants. Combined with proper lubrication and maintenance, plummer blocks perform exceptionally well in industries such as mining, steel plants, and marine operations, where machinery operates under continuous, high-load conditions.

What are the different types of plummer blocks?

The main types of plummer blocks include standard-duty, medium-duty, and heavy-duty designs, classified based on load capacity and operating conditions. They also vary by bearing type, such as spherical roller bearings or ball bearings. Some are designed with advanced seals for harsh environments, while others feature self-aligning capabilities for misaligned shafts. The choice depends on application requirements, load specifications, and environmental conditions to ensure optimal performance and longevity.

How do you lubricate a plummer block bearing?

Lubricating a plummer block bearing involves applying the correct type and amount of grease or oil through the designated lubrication points. Most plummer blocks have grease fittings that allow lubrication without disassembly. Regular lubrication prevents wear, reduces friction, and extends bearing life. It’s important to follow the manufacturer’s recommendations regarding lubrication intervals, quantity, and type to ensure optimal performance and prevent overheating or premature bearing failure.

How do you select the right size plummer block?

Selecting the right size plummer block involves determining the shaft diameter, bearing type, and load capacity required for your application. You should also consider environmental factors, such as exposure to dust, moisture, or chemicals, which may influence material choice and sealing options. Consulting manufacturer catalogs or engineering guidelines ensures the plummer block fits correctly, provides proper alignment, and supports operational demands without compromising performance or lifespan.

What is the working principle of plummer block?

The working principle of a plummer block is to house and secure a bearing that supports a rotating shaft, allowing smooth motion while reducing friction and wear. The plummer block’s split housing protects the bearing from contaminants and enables easy inspection, lubrication, or replacement. It ensures proper alignment, supports radial and axial loads, and distributes stress evenly along the shaft, making it a reliable component in heavy-duty machinery.